Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Understanding the China Spray Hose Assembly Machine: A Revolution in Industrial Automation

In recent years, the demand for efficient and reliable spray hose assemblies has grown significantly across various industries, from agriculture to manufacturing and automotive. At the heart of this demand is the China spray hose assembly machine, a game-changing innovation that is transforming the way spray hoses are assembled in large volumes. In this article, we will explore the various aspects of these machines, their features, benefits, and their applications in different industries.

What is a China Spray Hose Assembly Machine?

A China spray hose assembly machine is a highly specialized automated system designed to efficiently assemble spray hoses, a crucial component in many industrial and consumer products. These machines can handle tasks like crimping, sealing, and cutting hoses with precision and speed, significantly improving the production process. With the rise of mass production and the need for high-quality assembly, these machines have become essential in meeting both demand and quality control standards.

The Evolution of Spray Hose Assemblies in Industry

Before the advent, the process of assembling spray hoses was largely manual, requiring significant labor and time. Workers would manually insert fittings, crimp hoses, and inspect each connection. While this process was effective, it often led to inconsistencies in quality, longer production times, and increased labor costs.

As industries scaled up, the need for automated solutions became evident. The China's machine emerged as a solution to these challenges. These machines allowed manufacturers to meet higher production quotas without compromising on the quality of the hose assemblies. Today, these machines are capable of performing complex tasks that previously required multiple manual steps, reducing the potential for human error and increasing overall productivity.

Key Features of the China Spray Hose Assembly Machine

-

Automated Operation

One of the standout features is its ability to operate fully automatically. From feeding hoses into the system to crimping and sealing fittings, everything is done by the machine. This reduces the need for human intervention and ensures a consistent and reliable output. -

High-Speed Performance

These machines are built for speed, making them ideal for industries with high-volume production demands. Whether you're producing spray hoses for agricultural sprayers or automotive applications, the China's machine can deliver a large number of high-quality hose assemblies in a short amount of time. -

Precision and Accuracy

Precision is crucial in hose assembly, especially when working with components that need to withstand high pressure or extreme temperatures. The China's machine is equipped with advanced sensors and control systems to ensure that each hose is assembled to exact specifications. -

Customization Capabilities

Some models come with the ability to customize the assembly process according to the specific requirements of the customer. This includes adjusting the crimping force, hose length, and even the type of fitting used. This flexibility makes these machines ideal for various applications. -

Durability and Reliability

Built with industrial-grade materials, these machines are designed for continuous use in demanding environments. Whether you’re operating in a factory setting or a high-volume production facility, the spray hose assembly machine is engineered to provide long-term performance without frequent breakdowns.

Benefits of Using a China Spray Hose Assembly Machine

The integration into manufacturing processes offers numerous benefits, both from an operational and economic perspective.

1. Increased Productivity

One of the most immediate advantages of using these machines is the boost in productivity. With automation, manufacturers can meet higher production quotas, reducing the time needed to assemble spray hoses. This is especially important in industries where there is a constant demand for spray hose products.

2. Improved Quality Control

Automation also leads to more consistent quality. Since the process is machine-controlled, the potential for human error is minimized, leading to higher precision in every hose assembly. This ensures that each product meets the required standards, reducing defects and returns.

3. Lower Labor Costs

With the reduction in manual labor, companies can significantly lower their labor costs. The need for skilled workers to manually assemble hoses is reduced, and the workforce can be redirected to other areas of production or maintenance, further optimizing resource allocation.

4. Enhanced Safety

Automating the assembly process also improves workplace safety. Operators no longer have to work with sharp tools or perform repetitive manual tasks, reducing the risk of injury. The machine's design incorporates safety features such as emergency stop buttons, safety shields, and automated diagnostics to ensure smooth and safe operation.

5. Better Flexibility in Production

The versatility of these machines allows manufacturers to switch between different types of hose assemblies easily. Whether producing standard spray hoses or customized variations for specific industries, the China spray hose assembly machine can handle a range of products with minimal downtime or setup changes.

Applications of the China Spray Hose Assembly Machine

The versatility makes it an indispensable tool in several industries. Here are a few key sectors where these machines are widely used:

1. Agriculture

In the agricultural industry, spray hoses are essential for spraying pesticides, herbicides, and fertilizers on crops. The spray hose assembly machine plays a critical role in ensuring that these hoses are assembled quickly and accurately. High-quality hoses are necessary for preventing leaks or ruptures during operation, which could lead to costly wastage of chemicals or even crop damage.

2. Automotive

Spray hoses are commonly used in automotive applications for fluid delivery, such as brake fluid, power steering fluid, and windshield washer fluid. These hoses must meet strict safety and performance standards, making the spray hose assembly machine a key component in the automotive manufacturing process.

3. Consumer Goods

Many consumer products, such as garden sprayers and power washers, rely on spray hoses to function effectively. Manufacturers of these products use the spray hose assembly machines to produce durable, reliable hoses that can withstand wear and tear while maintaining a high level of performance.

4. Industrial Manufacturing

In industrial settings, spray hoses are often used for cleaning purposes, cooling systems, or fluid transfer. The ability to produce large quantities of high-quality spray hoses quickly and accurately is crucial in these environments, making the China spray hose assembly machine an essential tool in many factories.

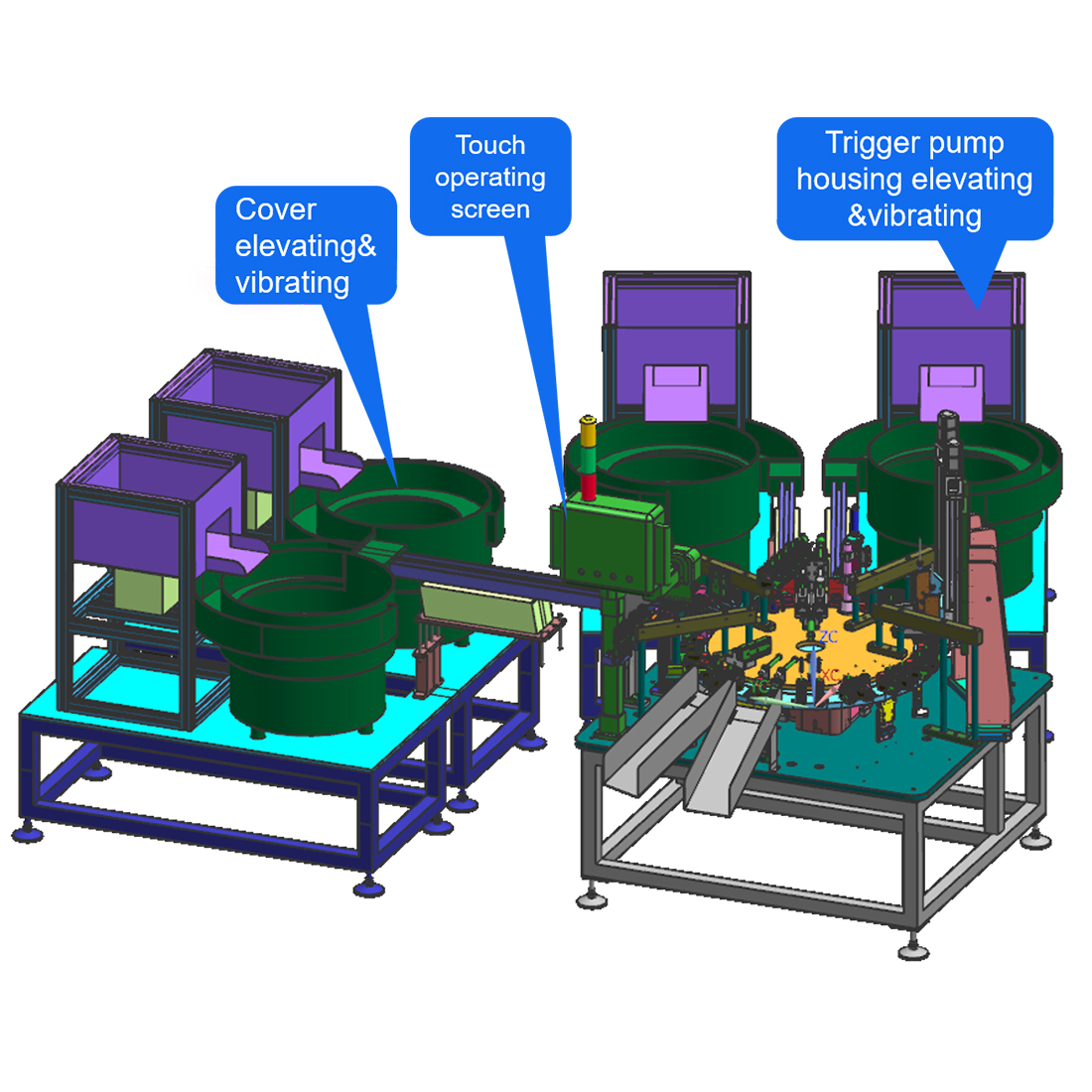

China Mini Trigger Assembly Machine Supplier: A Vital Role in Hose Production

When it comes to assembling spray hoses, the China mini trigger assembly machine is often used alongside the larger hose assembly machines. This smaller, more specialized machine is used to attach mini triggers or spray nozzles to the hoses, completing the assembly process. A reliable China mini trigger assembly machine supplier can provide manufacturers with the tools they need to produce a wide variety of hose products with different trigger mechanisms, ensuring versatility and efficiency in production.

Choosing the Right China Spray Hose Assembly Machine

With so many options available on the market, selecting the right China spray hose assembly machine for your business can be a daunting task. When evaluating machines, consider the following factors:

- Production Capacity: Choose a machine that can handle the volume of spray hoses you need to produce without compromising on quality.

- Customization Options: Ensure the machine can be tailored to meet your specific needs, whether you're assembling standard or specialized hoses.

- Support and Service: Look for a supplier that offers comprehensive customer support, including training, maintenance, and troubleshooting services.

- Price vs. Quality: While price is an important consideration, it’s crucial to balance cost with the long-term benefits of a high-quality, durable machine.

Conclusion

The China spray hose assembly machine represents a significant leap forward in manufacturing technology, offering a combination of speed, precision, and cost-effectiveness. As industries around the world continue to evolve and demand higher production capabilities, these machines will play a critical role in ensuring that manufacturers can meet those needs. Whether you're in agriculture, automotive, or industrial manufacturing, investing in a China spray hose assembly machine can greatly enhance your production process, improve efficiency, and reduce costs.