Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

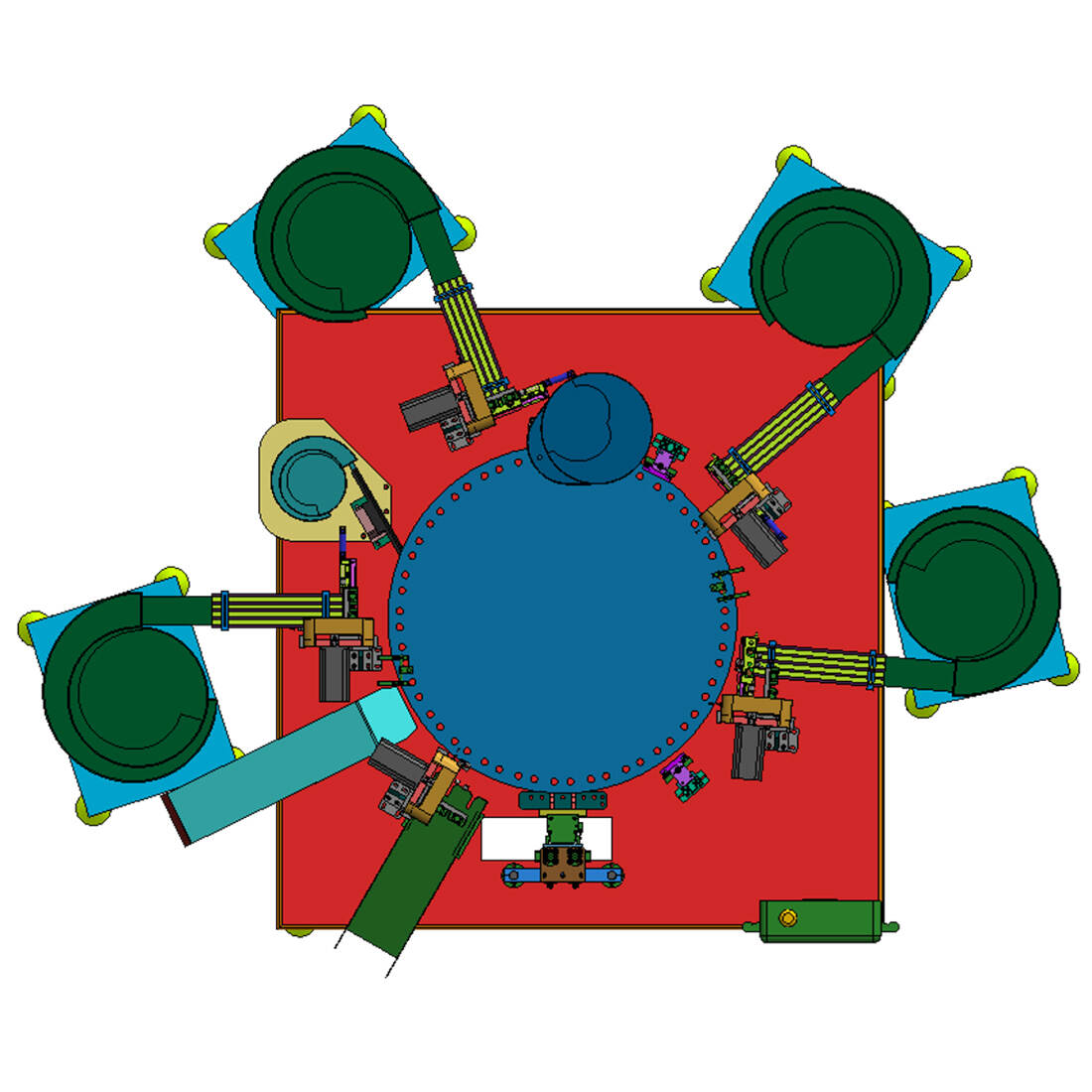

trigger sprayer tube assembling machine

Trigger sprayers are widely used in products like disinfectants,garden sprays,and household cleaners.With growing market demands and the need for fast-paced production,manufacturers are increasingly investing in trigger sprayer tube assembling machines.Choosing the right supplier is key—and Songrock delivers cutting-edge automation for the global packaging industry.

Introduction:Understanding Trigger Sprayer Tube Assembly

Trigger sprayers involve multiple components:actuator,shroud,pump engine,spring,closure,and dip tube.Assembling them manually is labor-intensive and inconsistent.A trigger sprayer tube assembling machine automates this process,ensuring precise alignment,secure fittings,and consistent performance.

Why Songrock Is the Leading Trigger Sprayer Tube Assembling Machine Manufacturer

1.Complete Automation,From Feeding to Assembly

Songrock machines fully automate feeding,insertion,pressing,and quality checking of the trigger sprayer’s dip tube component.Operators only need to monitor and maintain the machine,significantly cutting labor costs.

2.Enhanced Compatibility and Flexibility

Compatible with multiple tube lengths and diameters,Songrock’s trigger sprayer tube assembling machines are designed for seamless integration into any production workflow,whether you're producing 10,000 or 1 million units per day.

3.Intelligent Quality Control

Each machine is equipped with smart sensors and rejection systems to detect faulty tubes or misalignments.As your trigger sprayer tube assembling machine partner,Songrock ensures every unit meets strict quality standards.

4.Low Maintenance,High Uptime

Thanks to its modular design and high-quality components,Songrock machines require minimal maintenance while offering outstanding durability—making it a top choice for companies seeking long-term ROI.

Key Features of Songrock Trigger Sprayer Tube Assembling Machine

Speed:Up to 120 pieces/min

Tube Length Compatibility:100–300mm

Control System:Mitsubishi/Siemens PLC

Safety Features:Emergency stop,enclosed operation system

Output Accuracy:>99.5%qualified rate

5 Use Cases for Trigger Sprayer Tube Assembly

Disinfectant Bottles

Plant Sprayers

Cleaning Chemicals

Cosmetic Sprays

Industrial Chemicals

As the packaging industry evolves,manufacturers need flexible solutions.Songrock provides trigger sprayer tube assembling machines that cater to this dynamic market with ease.

Why Global Brands Trust Songrock

Reliable Production Line Integration

Training and After-Sales Support

Export-Ready Compliance(CE,UL,ISO,etc.)

Decades of Experience as a Trusted Supplier

From startups to multinational conglomerates,many rely on Songrock to provide dependable machinery that enhances efficiency and ensures compliance with global standards.

Customer Success Stories

"Before using Songrock machines,we faced frequent product rejections.Now,our assembly accuracy is above 99.5%."

—Jane Luo,Cleaning Product Manufacturer,Vietnam

“With Songrock’s engineering support,we customized the machine for 5 different tube lengths.It’s now the backbone of our sprayer production line.”

—Martin Grey,Industrial Chemicals Ltd,UK

Choosing the right trigger sprayer tube assembling machine can significantly impact your factory’s output and profitability.With Songrock,you're not just investing in a machine—you're partnering with a company that understands production,automation,and customer success.

For unmatched performance and service,make Songrock your go-to source for trigger sprayer tube assembling machines.