Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

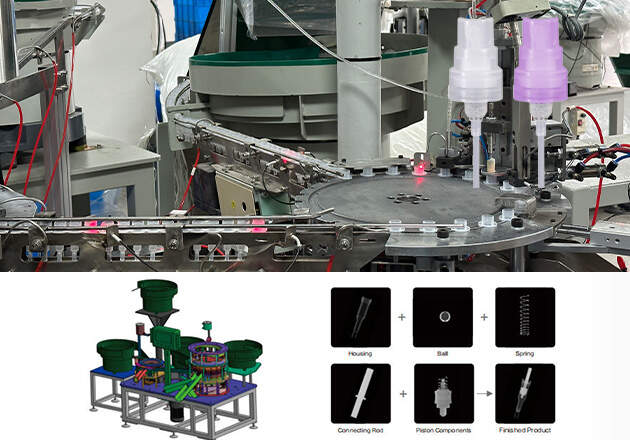

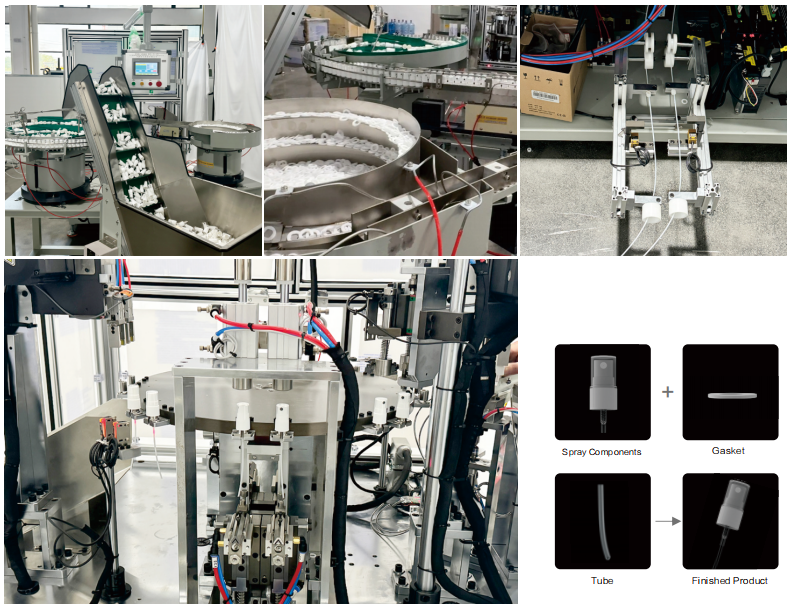

How a Mist Sprayer Assembly Machine Can Revolutionize Your Production Line

Imagine a production line where every mist sprayer is assembled with flawless precision, where downtime is a rarity, and where efficiency isn't just a goal—it's a guarantee. For manufacturers in cosmetics, pharmaceuticals, and household chemicals, achieving this level of perfection hinges on one critical investment: a high-performance mist sprayer assembly machine. This article explores how these machines work, their benefits, and what to consider when integrating them into your operations.

What Is a Mist Sprayer Assembly Machine?

A mist sprayer assembly machine is a specialized automated system designed to assemble mist sprayers—components including bottles, pumps, actuators, and caps—with high speed, accuracy, and consistency. These machines are engineered to handle various sizes and materials, such as plastic, glass, and metal, making them indispensable for industries requiring reliable and efficient packaging solutions.

Key Benefits of Automating Mist Sprayer Assembly

Investing in an automated assembly system offers tangible advantages:

-

Increased Production Speed:

Machines can assemble thousands of units per hour, far surpassing manual capabilities. -

Enhanced Precision and Consistency:

Automated systems minimize human error, ensuring every sprayer meets quality standards. -

Reduced Labor Costs:

Automation lowers dependency on manual labor, cutting long-term operational expenses. -

Scalability:

Whether you’re a startup or an established brand, these machines grow with your production needs. -

Hygiene and Safety:

Closed systems reduce contamination risks, critical for pharmaceuticals and cosmetics.

Types of Mist Sprayer Assembly Machines

Different production requirements call for different machines:

-

Semi-Automatic Machines: Ideal for small batches or custom orders, allowing operator involvement for flexibility.

-

Fully Automatic Machines: Designed for high-volume production, with minimal human intervention.

-

Rotary Assembly Systems: Use rotating stations for simultaneous multi-step assembly, maximizing output.

-

In-Line Systems: Integrate seamlessly into existing production lines for continuous workflow.

Features to Look for in a Mist Sprayer Assembly Machine

When selecting a machine, consider these factors:

-

Versatility: Can it handle different bottle shapes, sizes, and materials?

-

Ease of Maintenance: Look for accessible components and clear diagnostic tools.

-

User-Friendly Interface: Intuitive controls reduce training time and errors.

-

Durability: Robust construction ensures longevity even under high-demand conditions.

-

Compliance: Ensure the machine meets industry standards (e.g., ISO, GMP for pharmaceuticals).

Why Choose Songrock's Mist Sprayer Assembly Machines?

At Songrock, we combine engineering excellence with industry insight to deliver assembly machines that redefine efficiency. Our solutions include:

-

Customizable machines tailored to your product specifications.

-

Advanced sensors and AI-driven quality control for defect detection.

-

Comprehensive after-sales support, including training and maintenance.

-

Energy-efficient designs to reduce your carbon footprint and operational costs.

With Songrock, you’re not just buying a machine—you’re investing in a partnership dedicated to your success.

Your Turn to Ask!

Have questions about integrating a mist sprayer assembly machine into your production line? Wondering about customization options or technical specifications? We're here to help! Leave a comment below with your thoughts or challenges, or contact Songrock directly for a personalized consultation. Let's optimize your production together—share your needs and let's start a conversation!