Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Clamp Pump Assembly Machine from China: Enhancing Efficiency in Manufacturing

In the world of manufacturing, precision, speed, and efficiency are crucial for staying competitive. A clamp pump assembly machine plays a vital role in the production of liquid dispensing pumps, which are widely used in industries like cosmetics, pharmaceuticals, and household products. With the rise of automated machinery, China has become a key player in the production and distribution of clamp pump assembly machines, offering high-quality, cost-effective solutions for manufacturers worldwide.

This article explores the advantages, technical features, and applications of clamp pump assembly machines from China. We’ll also delve into how these machines are transforming production lines and why many companies rely on Chinese manufacturers for their assembly needs.

What is a Clamp Pump Assembly Machine?

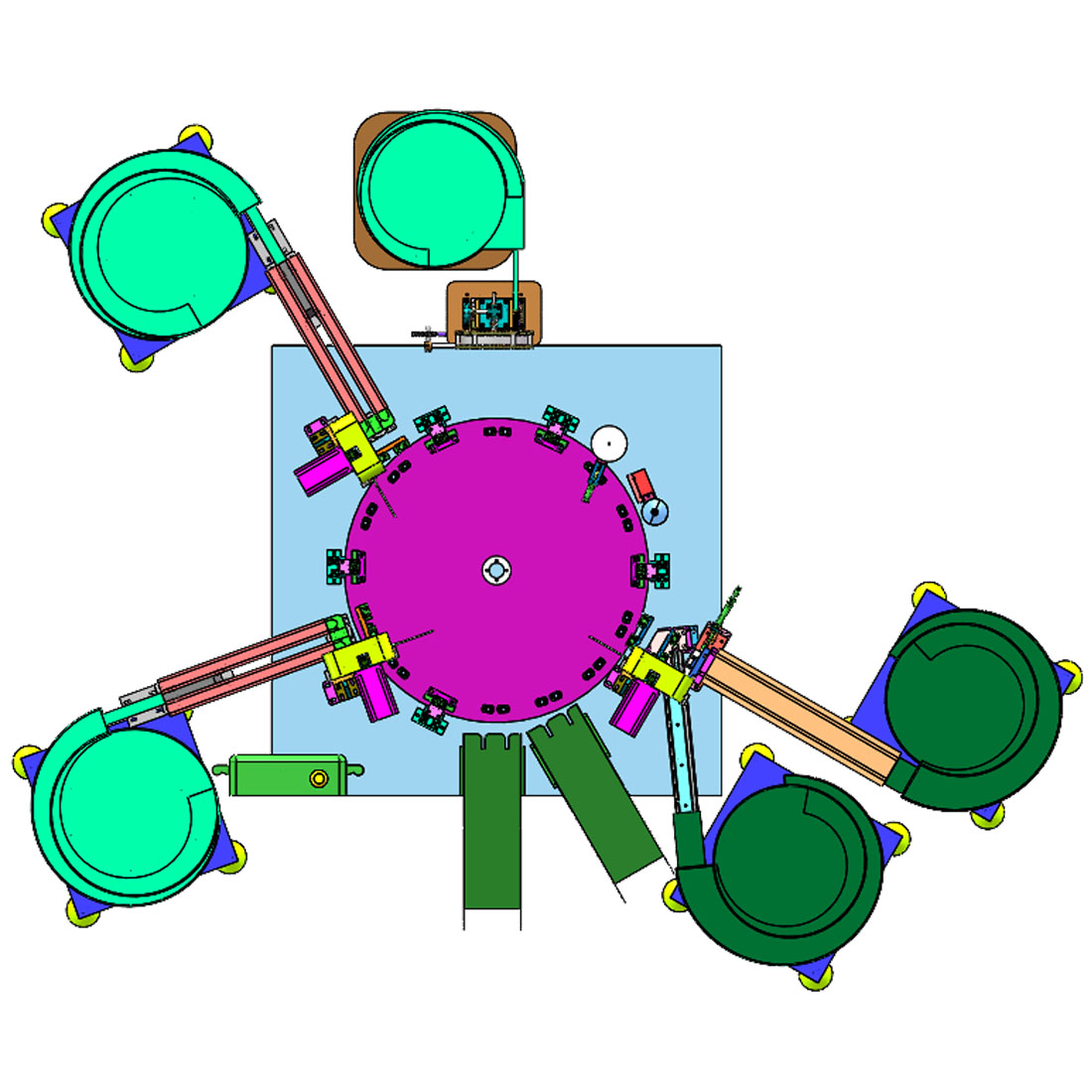

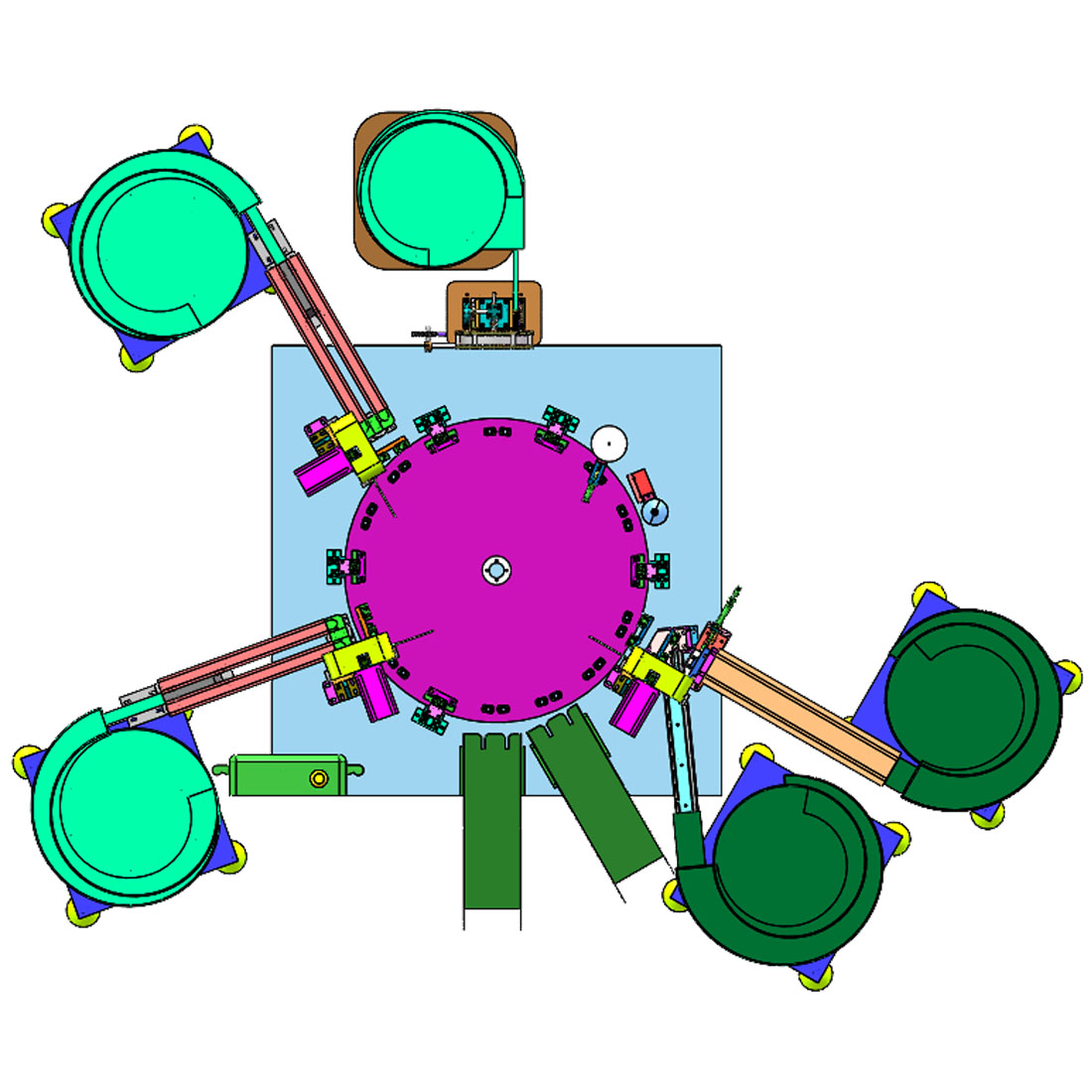

A clamp pump assembly machine is an automated system designed to assemble lotion pumps, trigger sprayers, and other dispensing pumps used in various industries. These machines are equipped with clamps that securely hold the pump components in place during the assembly process, ensuring precision and consistency.

The primary function of the clamp pump assembly machine is to automate the joining of components like the pump mechanism, bottle neck, and actuator. This reduces the need for manual labor and minimizes the risk of human error, resulting in faster production and improved product quality.

Advantages of Using a Clamp Pump Assembly Machine from China

1. Cost-Effectiveness

China has become a global leader in manufacturing automation, thanks to its advanced technology and competitive labor costs. Clamp pump assembly machines from China offer excellent value for money without compromising on quality. By sourcing these machines, companies can achieve a high return on investment (ROI) through increased productivity and reduced operational costs.

2. Precision and Consistency

Clamp pump assembly machines are engineered for precision, ensuring that each pump is assembled to the highest standards. With advanced control systems, these machines can detect inconsistencies or defects, automatically adjusting to ensure that every unit is correctly assembled. This level of consistency is particularly important in industries like cosmetics, where uniformity is key to customer satisfaction.

3. Increased Production Speed

One of the key benefits of clamp pump assembly machines is their ability to significantly speed up the production process. By automating the assembly of complex components, these machines can assemble hundreds or even thousands of pumps per day. This allows manufacturers to meet high demand and reduce lead times.

4. Customizable Features

Many manufacturers in China offer customizable clamp pump assembly machines to suit specific production needs. Whether you require a machine that can assemble different pump types or one that operates at a higher speed, Chinese suppliers can tailor their machines to meet your requirements. This flexibility makes it easier for companies to scale their operations and meet varying market demands.

5. Durability and Reliability

Chinese clamp pump assembly machines are known for their durability. Constructed using high-quality materials, these machines are built to withstand long hours of operation without failure. This reliability is essential in a production environment where downtime can be costly.

Key Technical Features of Clamp Pump Assembly Machines from China

Clamp pump assembly machines come equipped with several advanced features that ensure seamless operation. Here are some of the key technical aspects:

1. Automatic Component Feeding and Placement

One of the standout features of a clamp pump assembly machine is its ability to automatically feed and place components. The machine can automatically pick up pump components from storage bins, accurately position them, and secure them in place. This minimizes manual labor and improves assembly speed.

2. Servo Motors for Precise Control

Most clamp pump assembly machines are equipped with servo motors that offer precise control over the assembly process. These motors allow for smooth, consistent movements, reducing the chances of errors and improving the overall efficiency of the machine.

3. Advanced Control System

The control system of a clamp pump assembly machine allows for easy programming and monitoring of the assembly process. Operators can adjust settings, check performance metrics, and troubleshoot potential issues through a user-friendly interface.

4. Built-in Quality Control Mechanisms

Modern clamp pump assembly machines from China often include built-in quality control features. These systems can detect faulty components or assembly errors in real-time, ensuring that only high-quality pumps make it to the final stage of production.

5. Energy Efficiency

Energy efficiency is a key consideration in modern manufacturing. Many clamp pump assembly machines are designed to consume less power while maintaining high performance. This makes them an environmentally friendly option that can help businesses reduce their overall energy costs.

Applications of Clamp Pump Assembly Machines

Clamp pump assembly machines are used in a wide range of industries where liquid dispensing pumps are essential. Some of the most common applications include:

1. Cosmetics and Personal Care

The cosmetics industry relies heavily on lotion pumps and spray pumps for packaging products like lotions, shampoos, conditioners, and perfumes. Clamp pump assembly machines from China offer a fast, cost-effective way to assemble these products in large quantities. The high precision of these machines ensures that pumps are consistently assembled, resulting in a reliable product that meets customer expectations.

2. Pharmaceuticals

In the pharmaceutical industry, clamp pump assembly machines are used to assemble pumps for dispensing medicines, sanitizers, and other liquid-based products. Given the strict quality and safety regulations in this industry, the ability to achieve high precision and consistency is critical. Chinese manufacturers have mastered the production of reliable and accurate assembly machines that meet these high standards.

3. Household Products

From cleaning supplies to air fresheners, many household products require dispensing pumps for packaging. Clamp pump assembly machines help manufacturers assemble pumps quickly and efficiently, enabling them to meet market demand without compromising on quality.

4. Food and Beverage

Some food and beverage products, such as oils, sauces, and condiments, also rely on dispensing pumps for packaging. Clamp pump assembly machines ensure that these pumps are assembled to high standards, preventing leaks and ensuring the products are safe for consumption.

Choosing the Right Clamp Pump Assembly Machine Supplier

When selecting a clamp pump assembly machine, it’s important to consider several factors to ensure you’re investing in the right equipment for your needs. Here are a few tips for choosing the right supplier:

1. Experience and Reputation

Choose a supplier with a proven track record in manufacturing high-quality clamp pump assembly machines. Look for manufacturers who have experience working with clients in your industry and can provide references or case studies.

2. Customization Options

Different businesses have different needs, so it’s important to choose a supplier that offers customizable options. Whether you need a machine that can handle different types of pumps or one that can integrate into your existing production line, make sure the supplier can accommodate your specific requirements.

3. After-Sales Support

Ensure that the supplier offers strong after-sales support, including installation, training, and ongoing maintenance. This is particularly important when investing in complex machinery, as you’ll need support to troubleshoot any issues that arise during operation.

4. Quality Assurance

Look for suppliers that offer quality assurance and adhere to international manufacturing standards. This will help ensure that the clamp pump assembly machine you receive is built to last and performs as expected.

The Future of Clamp Pump Assembly Machines from China

As the demand for automated solutions continues to grow, the future of clamp pump assembly machines looks promising. China is at the forefront of developing new technologies to improve the speed, efficiency, and flexibility of these machines. Innovations in AI and machine learning could lead to even smarter machines that can adapt to different production needs in real-time.

Additionally, the focus on sustainability and energy efficiency will likely continue to drive advancements in machine design. As manufacturers seek to reduce their carbon footprint, Chinese suppliers are expected to lead the way in offering eco-friendly, energy-efficient solutions.

Conclusion

The clamp pump assembly machine from China is a game-changer in the manufacturing process, offering businesses around the world a reliable, cost-effective way to automate the assembly of liquid dispensing pumps. With advanced features, customizable options, and a proven track record of reliability, these machines are the backbone of industries ranging from cosmetics to pharmaceuticals. By investing in a clamp pump assembly machine, companies can increase production speed, reduce costs, and ensure consistent product quality. As automation technology continues to evolve, the future looks bright for clamp pump assembly machines, and the industry as a whole.