Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Trusted Trigger Sprayer Assembly Machine Suppliers for Automated Production

Trigger sprayers are widely used in cleaning agents, disinfectants, gardening sprays and other fields, and have extremely high requirements for assembly technology. Traditional manual assembly methods are inefficient and have unstable yields, and can no longer meet the needs of the rapidly developing market. Therefore, more and more manufacturers are turning to automated equipment and looking for professional trigger sprayer assembly machine suppliers to achieve efficient and high-quality sprayer production.

1. Complexity of trigger sprayer assembly structure

A typical trigger sprayer includes the following components:

Nozzle

Valve core

Spring

Piston

Seal ring

Housing and buckle cover

These parts need to be assembled in a strict order, and the sealing, elasticity and spray angle consistency must be maintained. Automated assembly has become a trend.

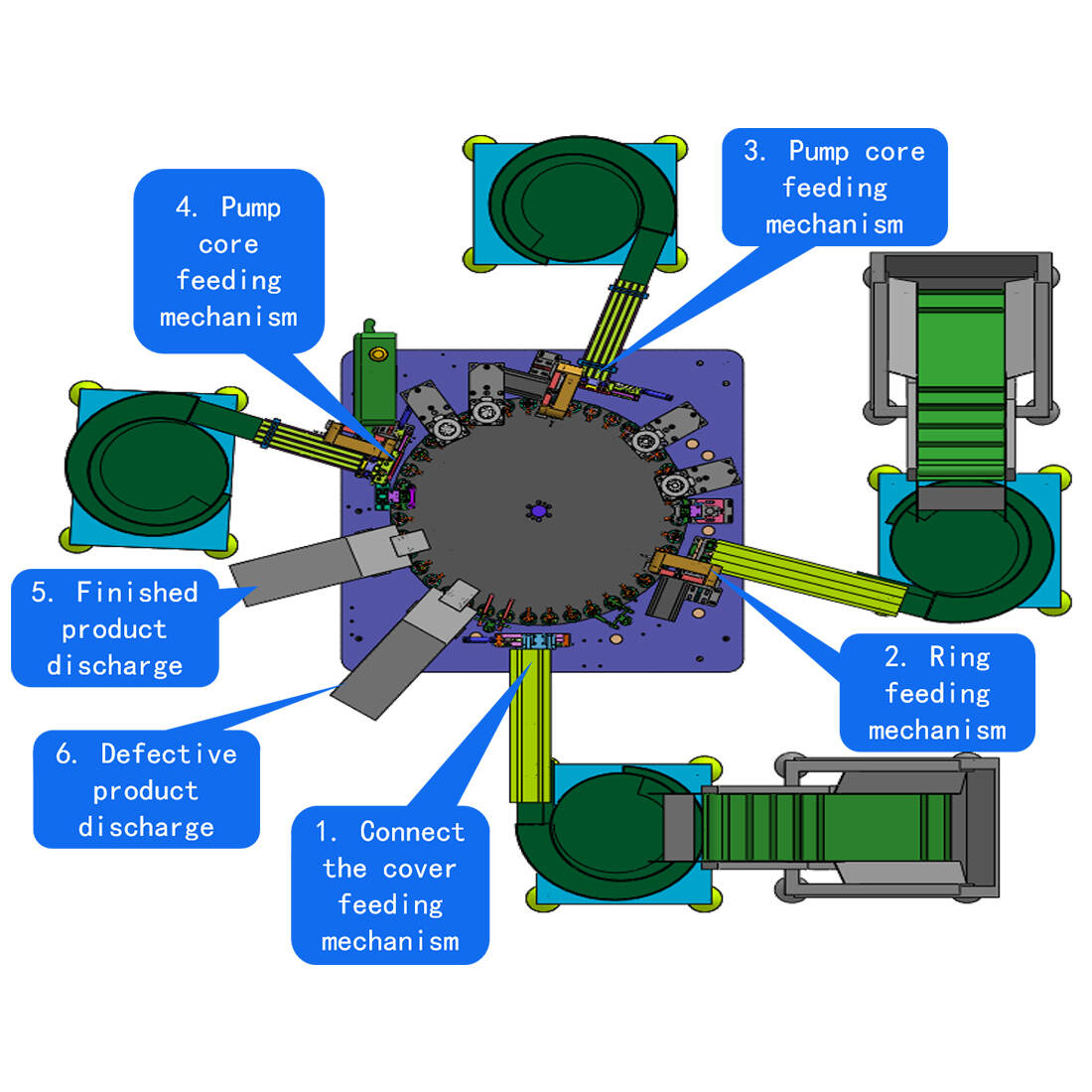

2. Core modules of automatic assembly machine

Multi-station turntable structure: improve the beat speed

Servo positioning feeding system: ensure the consistency of parts direction

Intelligent detection system: automatically identify and remove defective products

Fully automatic feeding system: save labor

3. Aspects to pay attention to when choosing a high-quality trigger sprayer assembly machine supplier

Whether it focuses on the sprayer industry: understand industry standards and needs.

Whether it has customization capabilities: such as changing the spray head model, bottle mouth size, etc.

Whether it has experience in serving global customers: whether it supports remote debugging and overseas maintenance.

Whether it provides a whole line linkage design: such as filling → assembly → testing → packaging integration.

4. Typical cooperation cases of trigger sprayer assembly machine suppliers (illustration):

Cooperate with a European cleaning brand to produce tens of millions of trigger sprayers per year;

Provide 4-channel high-speed assembly machines for Southeast Asian detergent companies, with a daily output of more than 80,000.

5. Procurement suggestions for trigger sprayer assembly machine suppliers:

Prepare samples and 3D drawings in advance to facilitate quick evaluation of trigger sprayer assembly machine suppliers.

Pay attention to whether it is equipped with a module replaceable system to meet different product needs.

Investigate whether the manufacturer has existing machines to test performance and stability.

Conclusion of trigger sprayer assembly machine supplier:

In the production of trigger sprayers, the accuracy and stability of automated assembly determine product quality and market competitiveness. Cooperating with an experienced trigger sprayer assembly machine supplier can not only shorten the production cycle, but also gain long-term advantages in cost control and yield rate.