Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

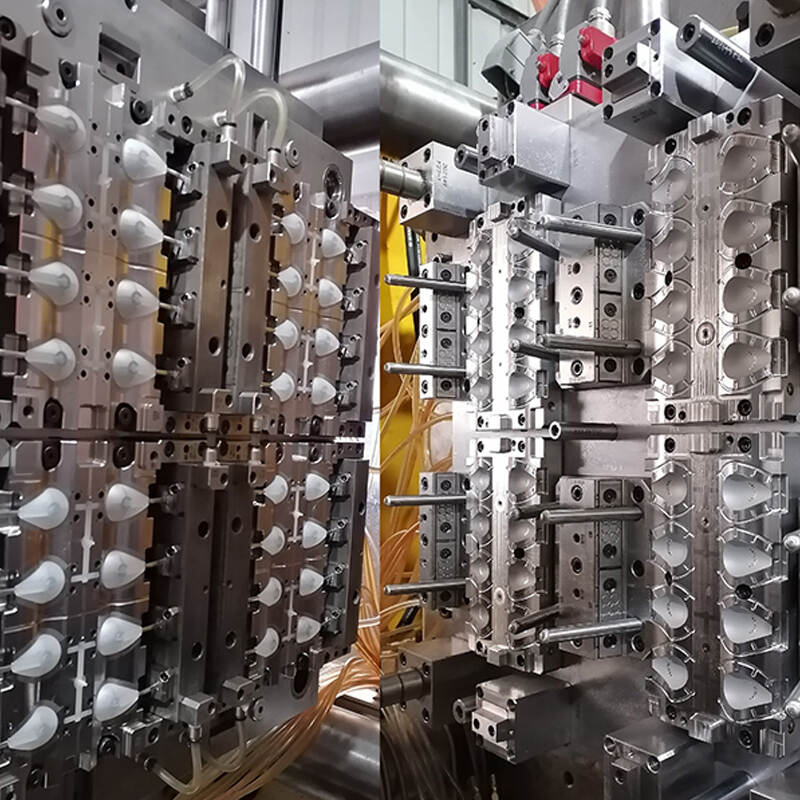

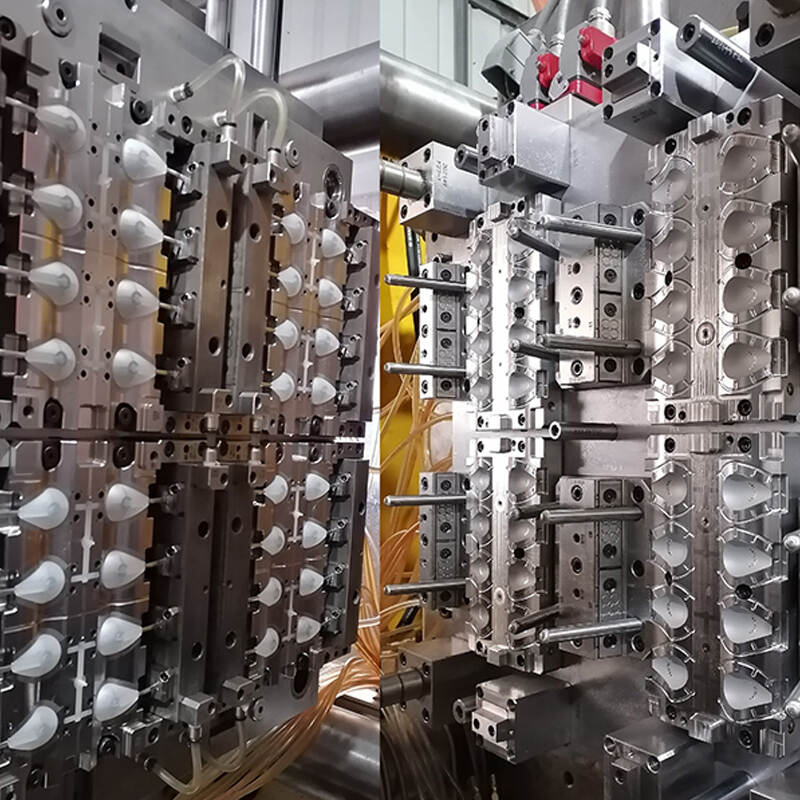

Sprayer Injection Mould: The Key to Efficient and Cost-Effective Production

Sprayer injection moulds are at the heart of many industries, particularly in the manufacturing of sprayers for various applications such as agriculture, cleaning, and personal care. These moulds are crucial in shaping the parts and components of sprayers, ensuring they function efficiently and effectively. In this blog, we will explore what a sprayer injection mould is, its advantages, how it contributes to mass production, and why it's essential to choose the right mould manufacturer for your business.

What is a Sprayer Injection Mould?

A sprayer injection mould is a tool used in the injection moulding process to create the components of sprayers. Injection moulding is a manufacturing process that involves injecting molten material into a mould to create precise and durable plastic parts. The mould is a critical aspect of this process, as it determines the shape, size, and quality of the final product. The moulds can produce various parts such as nozzles, handles, and other key components of sprayers.

The injection moulding process is particularly popular for producing large quantities of identical parts with high precision. When applied to sprayer production, this process enables manufacturers to create consistent, high-quality components quickly and efficiently.

Advantages of Using Sprayer Injection Moulds

Sprayer injection moulds provide several advantages that make them indispensable for mass production:

1. Precision and Consistency

One of the key benefits is the high level of precision they offer. Injection moulding allows manufacturers to create intricate designs with tight tolerances, which is essential for sprayer components that must fit together seamlessly. The process also ensures that each part is identical, ensuring consistency across large production runs.

2. Cost-Effectiveness

The initial investment in an injection mould can be significant, but the long-term savings it offers are substantial. Once the mould is created, it can be used to produce thousands or even millions of parts at a relatively low cost per unit. This makes the moulds a cost-effective solution for manufacturers looking to produce large quantities of sprayer components.

3. High Production Speed

Injection moulding is known for its speed, which is a critical factor in mass production. The moulds allow manufacturers to produce components in a matter of seconds, enabling high-volume production. This rapid production cycle reduces lead times and helps businesses meet customer demands more efficiently.

4. Durability and Longevity

The moulds are typically made from durable materials such as steel or aluminum, which can withstand the high pressures and temperatures involved in the injection moulding process. This durability ensures that the mould can be used for many production cycles without losing its accuracy or functionality. As a result, businesses can rely on their moulds for long-term production without the need for frequent replacements.

5. Material Versatility

Another advantage is their ability to work with a wide range of materials. Manufacturers can choose from various types of plastics, each offering different properties such as strength, flexibility, or chemical resistance. This flexibility allows for the customization of sprayer components based on specific requirements, whether the sprayer is intended for use in agriculture, cleaning, or personal care.

The Role of Sprayer Injection Moulds in Mass Production

Sprayer injection moulds are essential for mass production because they enable manufacturers to produce large quantities of high-quality sprayer components quickly and cost-effectively. The ability to produce identical parts in large volumes is particularly important in industries where sprayers are used, such as agriculture, where farmers rely on sprayers for pest control and fertilization, or in the cleaning industry, where consistent performance is critical.

1. Reducing Production Costs

One of the main reasons is the significant cost savings they offer in mass production. By producing thousands or millions of parts with a single mould, manufacturers can reduce the overall cost per unit, making their products more competitive in the market.

2. Ensuring Product Quality

In mass production, maintaining consistent quality is crucial. The moulds ensure that each component meets the required specifications, reducing the risk of defects or malfunctions. This is especially important in industries like agriculture and personal care, where the reliability of sprayers can directly impact the effectiveness of the product.

3. Customization Opportunities

While injection moulding is known for its ability to produce large volumes of identical parts, it also offers opportunities for customization. Manufacturers can create different moulds for various sprayer designs, allowing for product differentiation in the market. This flexibility is valuable for businesses looking to offer a range of sprayer models tailored to different customer needs.

Choosing the Right Sprayer Injection Mould Manufacturer

The quality and performance depend largely on the expertise of the manufacturer. Choosing the right mould supplier is critical for ensuring that your moulds meet your production needs and deliver the desired results.

1. Experience and Expertise

When selecting a sprayer injection mould manufacturer, it's essential to choose a company with extensive experience in the industry. An experienced manufacturer will have a deep understanding of the injection moulding process and be able to design moulds that are optimized for performance and longevity. Look for a supplier with a proven track record of producing high-quality moulds for sprayer components.

2. Customization Capabilities

Not all sprayers are the same, and your moulds should be designed to meet the specific requirements of your products. Choose a manufacturer that offers customization options and can work with you to develop moulds tailored to your needs. This includes designing moulds that accommodate different materials, sizes, and component shapes.

3. Quality Control

Quality is critical when it comes to sprayer injection moulds. A reliable manufacturer will have strict quality control measures in place to ensure that each mould meets the highest standards. This includes using high-quality materials for mould construction and conducting thorough testing to verify the mould's performance.

4. After-Sales Support

Injection moulds are long-term investments, and it's important to choose a manufacturer that offers ongoing support. This can include maintenance services, repair options, and technical assistance to ensure that your moulds continue to perform optimally throughout their lifespan.

5. Reputation in the Industry

Finally, consider the reputation of the manufacturer within the industry. Look for reviews, testimonials, or case studies that highlight the manufacturer's strengths and customer satisfaction. A reputable manufacturer will have a strong portfolio of successful projects and positive feedback from clients.

Case Study: China Sprayer Injection Mould Industry

The sprayer injection mould industry in China has become a major player in global manufacturing, offering high-quality moulds at competitive prices. Chinese manufacturers are known for their ability to produce large volumes of injection moulds for various industries, including agriculture, cleaning, and personal care. With state-of-the-art facilities and a skilled workforce, China sprayer injection mould suppliers are able to meet the demands of international markets, providing both standard and customized moulds to clients worldwide.

Chinese manufacturers have invested heavily in research and development, ensuring that their moulds are at the cutting edge of technology. This has allowed them to offer moulds that are not only cost-effective but also highly durable and efficient. Businesses looking to source injection moulds for sprayers often turn to China for their manufacturing needs, taking advantage of the country's expertise and competitive pricing.

Conclusion

Sprayer injection moulds are a vital component in the production of sprayers, offering numerous benefits such as precision, cost-effectiveness, and high production speed. For businesses involved in manufacturing sprayers, choosing the right mould supplier is essential for ensuring product quality and reducing production costs. With a wide range of materials and customization options available, the moulds provide the flexibility needed to meet the diverse needs of industries like agriculture, cleaning, and personal care.

As the demand for sprayers continues to grow, investing in high-quality sprayer injection moulds will be key to staying competitive in the market. Whether you're producing sprayers for agriculture, cleaning, or personal care, the right injection mould can help you achieve efficient and cost-effective production, ensuring your business's success in the long term.