Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Ferrule Assembly Machine Manufacturer: A Comprehensive Guide to Choosing the Right Supplier

The growing demand for precision and efficiency in manufacturing processes has led to an increasing reliance on automated equipment like ferrule assembly machines. For industries dealing with cables, wires, and connectors, these machines are critical in ensuring high-quality assembly processes. When looking for the right ferrule assembly machine manufacturer, there are several key factors to consider. In this article, we will explore the essential aspects of selecting a reliable manufacturer and how their products can optimize your production line.

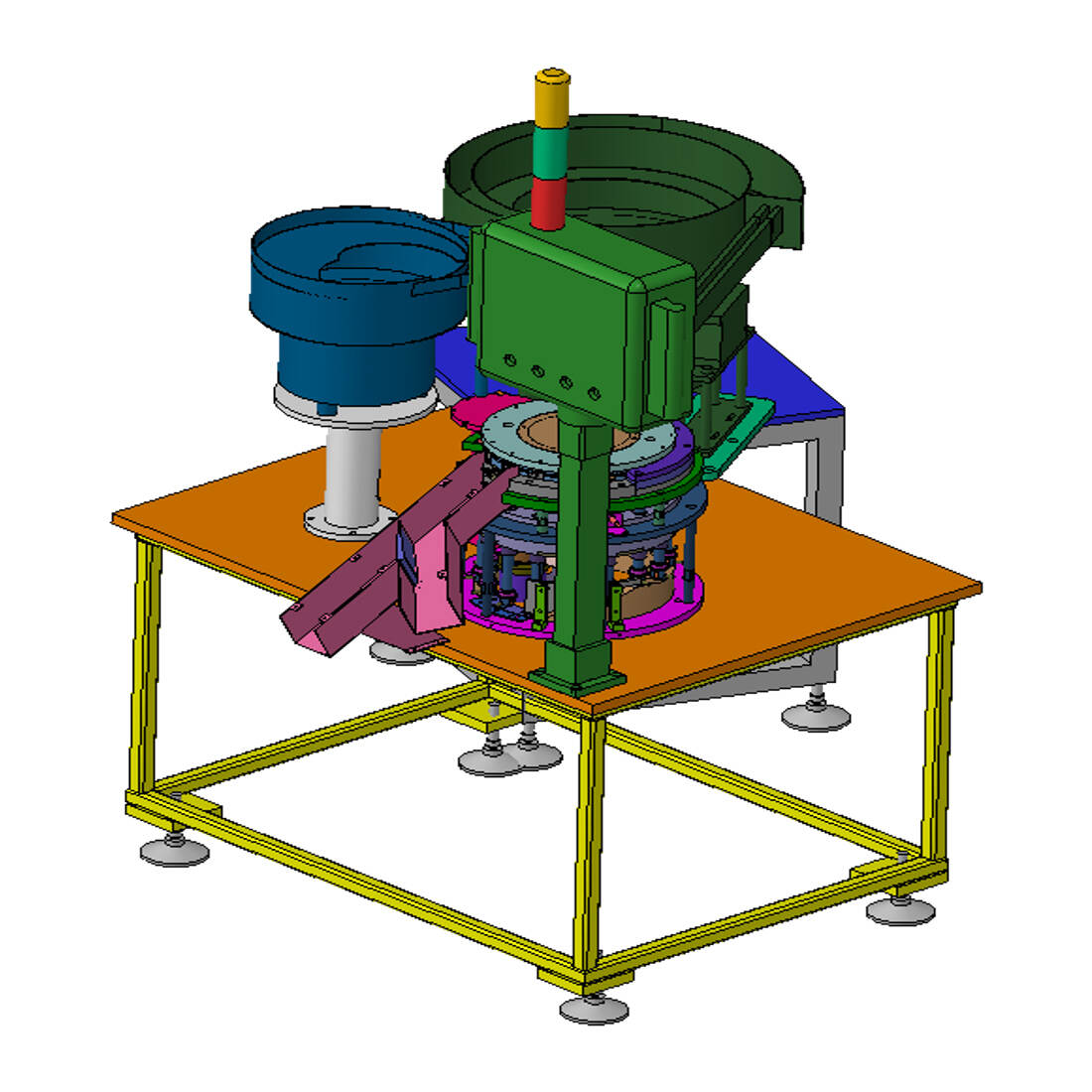

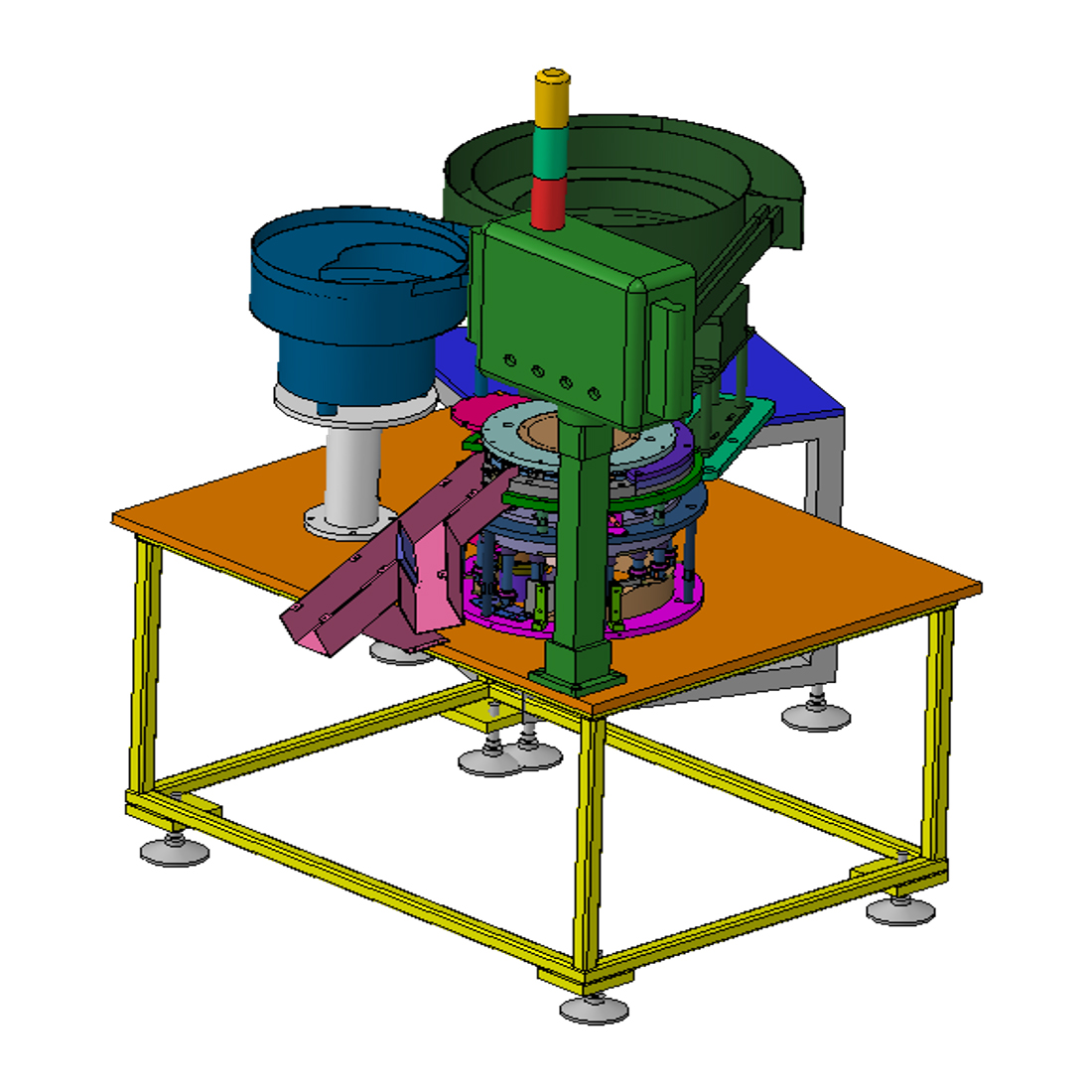

What is a Ferrule Assembly Machine?

A ferrule assembly machine is a type of automated equipment designed to install ferrules onto the ends of electrical wires or cables. Ferrules are small cylindrical tubes made from metals or conductive materials, and they are used to crimp wire ends for safe and efficient electrical connections. These machines automate the entire process, ensuring that each ferrule is applied uniformly and securely, which minimizes the risk of poor connections in electrical systems.

By working with an experienced ferrule assembly machine manufacturer, businesses can enhance their operational efficiency while ensuring compliance with industry standards.

Why Work with a Reputable Ferrule Assembly Machine Manufacturer?

When it comes to ferrule assembly machines, quality and reliability are critical. Partnering with a reputable manufacturer ensures you get a high-performance machine tailored to your specific production needs. A reliable manufacturer will not only offer a wide range of machine models but will also provide excellent after-sales support and customization options.

Here are some reasons why choosing the right ferrule assembly machine manufacturer is vital for your business:

High-Quality Production Output: A professional manufacturer designs machines that ensure consistency and accuracy in the assembly process. This reduces the likelihood of defects and enhances the overall quality of the final product.

Cost Efficiency: Investing in the right machine from a reputable manufacturer can significantly reduce labor costs and material waste. Automation speeds up the process while maintaining quality control, allowing you to produce more in less time.

Compliance with Industry Standards: Trusted manufacturers design their machines to meet international standards, such as ISO and CE certifications. This ensures your production process adheres to global safety and quality requirements.

Custom Solutions: Some industries have unique needs that require custom-built machines. By working with an experienced ferrule assembly machine manufacturer, you can receive machines that are tailored to fit your specific production requirements.

Key Factors to Consider When Choosing a Ferrule Assembly Machine Manufacturer

Choosing the right ferrule assembly machine manufacturer requires careful consideration of several factors. Below are some key points to keep in mind:

1. Industry Experience

One of the most important factors to evaluate is the manufacturer’s experience in the field. A manufacturer with years of experience will have a better understanding of the complexities involved in ferrule assembly. Experienced manufacturers are more likely to offer innovative solutions and advanced machine models designed to improve efficiency and performance.

2. Range of Products

A reliable manufacturer will offer a broad range of machine models suited to different production needs. Whether you need a machine for small-scale production or a high-capacity automated system, the manufacturer should have options that match your requirements.

3. Customization Options

Not all production lines are the same, and sometimes a standard machine may not meet your specific needs. A good manufacturer will offer customization options that allow you to modify the machine’s features to better suit your production process. This may include changes to the machine’s size, speed, or specific functionalities.

4. Technical Support and After-Sales Service

When choosing a manufacturer, it’s essential to consider the level of technical support and after-sales service they provide. Machines can sometimes malfunction, and having a dedicated support team ensures that any issues are quickly resolved to avoid production delays. Look for manufacturers that offer comprehensive training, maintenance services, and fast delivery of spare parts.

5. Reviews and Reputation

Before committing to a specific manufacturer, take the time to research their reputation. Customer reviews, testimonials, and case studies can provide valuable insights into the manufacturer’s reliability, customer service, and product quality. You can also reach out to other businesses that have worked with the manufacturer to get firsthand feedback on their experience.

6. Certifications and Compliance

Make sure the manufacturer adheres to relevant industry standards and certifications. Machines that are ISO or CE certified are generally more reliable and safer to use. Certifications ensure that the manufacturer follows strict quality control procedures during the production of their machines.

Benefits of Investing in a High-Quality Ferrule Assembly Machine

Investing in a high-quality machine from a reputable ferrule assembly machine manufacturer comes with several advantages that can enhance your production process:

1. Increased Efficiency and Productivity

One of the most significant advantages of using a high-quality ferrule assembly machine is the increase in production efficiency. These machines can process large volumes of wires quickly, reducing the time it takes to complete assembly tasks. This allows your production line to operate at higher speeds without compromising on quality.

2. Reduced Labor Costs

Automation eliminates the need for manual labor in the ferrule assembly process. This means you can reduce the number of employees needed for certain tasks, lowering labor costs and improving overall operational efficiency. The machine’s accuracy also reduces the risk of human error, leading to fewer defects and less material waste.

3. Consistent Quality

Consistency is key in any manufacturing process, and a ferrule assembly machine ensures uniform quality across all assembled products. With precise crimping and placement of ferrules, your products will meet the highest industry standards, reducing the likelihood of product recalls or failures in the field.

4. Customization for Specific Needs

A reliable ferrule assembly machine manufacturer can provide machines tailored to your production needs. Whether you need different wire sizes, ferrule types, or specialized crimping techniques, a customized machine can help streamline your process while maintaining quality.

Applications of Ferrule Assembly Machines

Ferrule assembly machines are widely used in various industries where high-quality electrical connections are essential. Some of the primary applications include:

Automotive Industry: Electrical systems in vehicles rely heavily on secure and reliable connections. Ferrule assembly machines ensure that wiring harnesses and other electrical components are assembled to precise specifications, improving safety and performance.

Aerospace Industry: In aerospace applications, where safety is paramount, ferrule assembly machines ensure that all electrical connections meet stringent quality standards.

Telecommunications: As telecommunications networks grow, the need for high-quality cable connections increases. Ferrule assembly machines help streamline the production of telecom cables, ensuring fast and reliable data transmission.

Electronics Manufacturing: Many electronic devices require precise wiring for proper functionality. Ferrule assembly machines are crucial in ensuring that these devices are built to last, with secure and consistent electrical connections.

Future Trends in Ferrule Assembly Machine Technology

As technology advances, ferrule assembly machine manufacturers are continuously innovating to meet the growing demands of various industries. Some of the emerging trends include:

1. Automation and AI Integration

The integration of artificial intelligence (AI) into ferrule assembly machines is expected to revolutionize the industry. AI can help machines self-correct during production, reducing the need for human intervention and minimizing downtime.

2. Energy-Efficient Machines

As environmental concerns grow, manufacturers are focusing on developing energy-efficient machines that reduce power consumption without compromising performance. This shift toward eco-friendly production is expected to benefit industries looking to reduce their carbon footprint.

3. Enhanced Connectivity

With the rise of Industry 4.0, ferrule assembly machines are becoming more connected. Machines equipped with IoT (Internet of Things) technology can communicate with other devices on the production line, optimizing performance and providing real-time data analytics for improved decision-making.

Conclusion

Choosing the right ferrule assembly machine manufacturer is a critical decision that can significantly impact your production process. By considering factors such as industry experience, customization options, and after-sales support, you can ensure that you invest in a high-quality machine that meets your needs. As industries continue to evolve, working with a reputable manufacturer will help you stay ahead of the competition by improving efficiency, reducing costs, and maintaining consistent product quality.

When searching for the best ferrule assembly machine manufacturer, prioritize those with a proven track record of reliability, innovation, and excellent customer service. With the right partner, you can optimize your production process and achieve long-term success.