Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Mini Assembly Machine Supplier: Revolutionizing Manufacturing with Cutting-Edge Solutions

In today's fast-paced industrial world, businesses rely heavily on advanced machinery to streamline production processes. Among these, mini assembly machines stand out due to their versatility, efficiency, and compact size. As industries grow, the demand for reliable mini assembly machine suppliers has skyrocketed. These suppliers provide high-quality machines that cater to various sectors, ranging from electronics to automotive. In this post, we will delve into the importance of mini assembly machines, key considerations when choosing a supplier, and how these machines are transforming modern manufacturing.

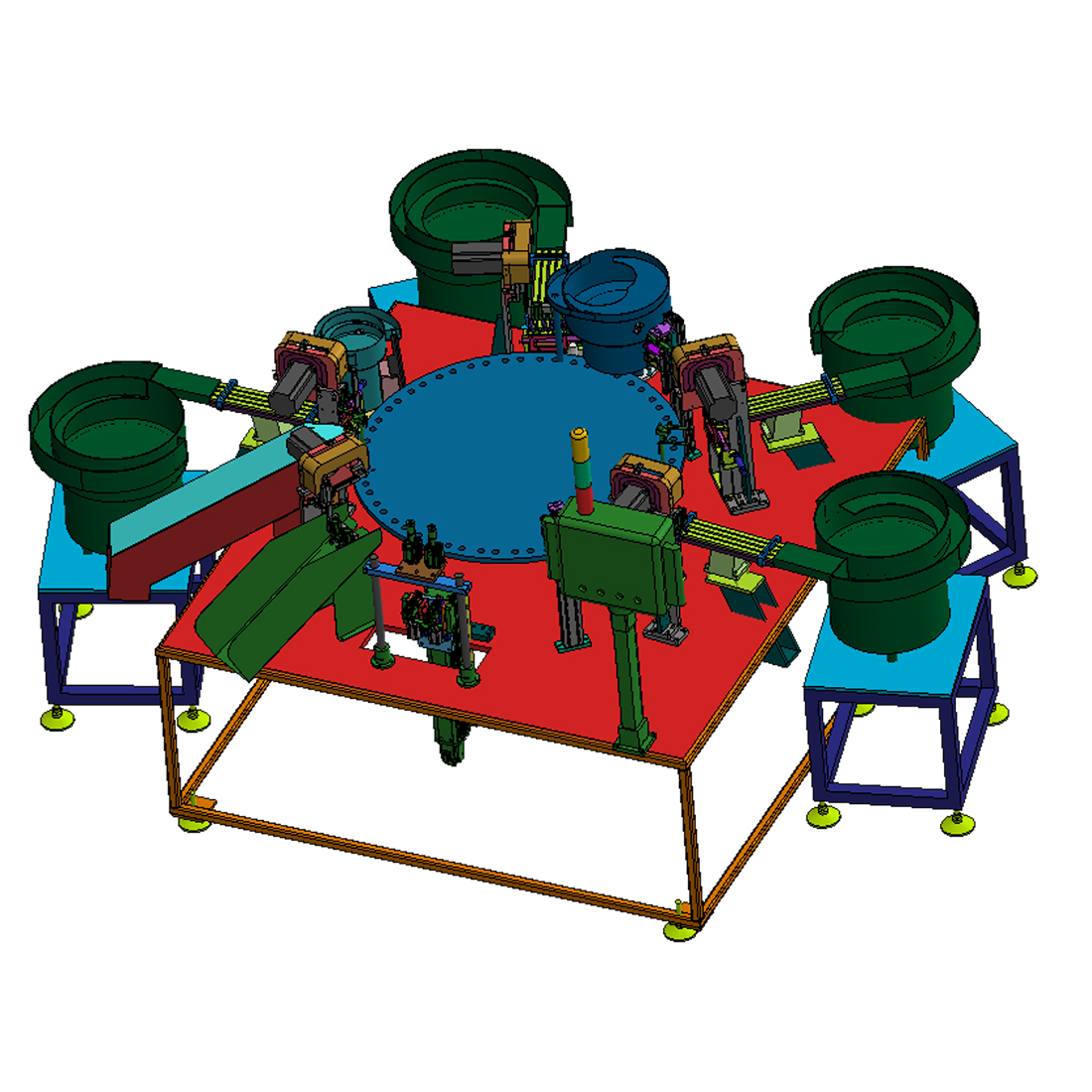

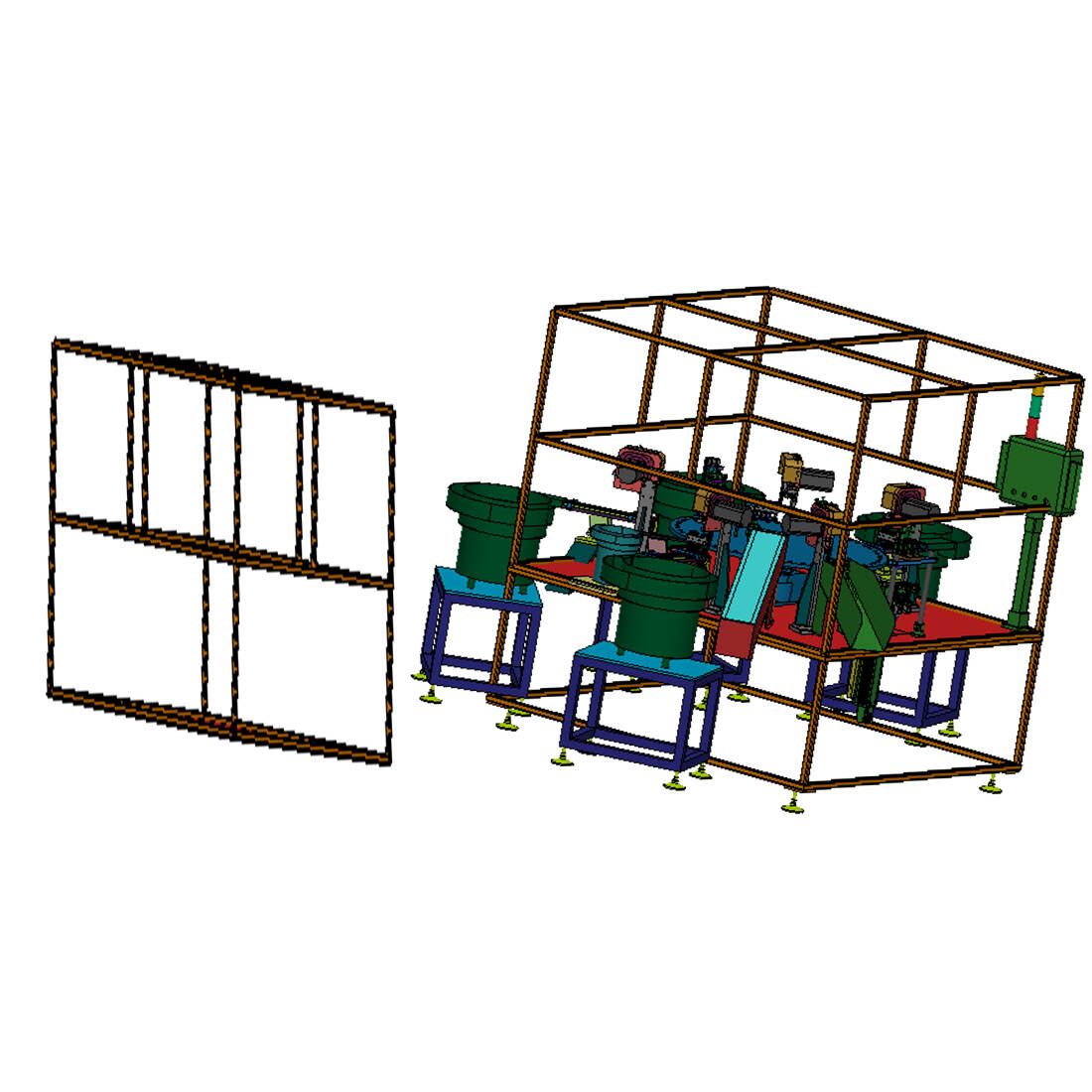

What is a Mini Assembly Machine?

A mini assembly machine is a compact, automated device used in the assembly of small components in various industries. These machines are designed to handle intricate tasks, such as assembling electronic components, fastening tiny parts, or even constructing small appliances. Their small size allows them to fit into limited spaces, making them ideal for manufacturers with space constraints. Despite their compactness, mini assembly machines are known for their high precision and efficiency.

Why Are Mini Assembly Machines in Demand?

Compact Design: Mini assembly machines are designed to save space, making them ideal for small production areas.

Cost-Effective: They offer a more affordable alternative to large-scale assembly lines without compromising quality.

High Precision: These machines are engineered to handle delicate components with great accuracy, which is crucial for industries like electronics.

Energy Efficient: With smaller motors and fewer parts, mini assembly machines tend to consume less energy, leading to lower operational costs.

The Role of a Mini Assembly Machine Supplier

Choosing the right mini assembly machine supplier is essential for ensuring your production runs smoothly. A reliable supplier not only provides high-quality machines but also offers support services, such as maintenance and troubleshooting, ensuring minimal downtime in operations. The best suppliers are those who understand the unique needs of different industries and offer customizable solutions.

Key Factors to Consider When Choosing a Mini Assembly Machine Supplier

Reputation and Experience

Reputation speaks volumes about a supplier's reliability. When selecting a mini assembly machine supplier, consider their track record and experience in the industry. Experienced suppliers are more likely to understand the nuances of various manufacturing processes and offer machines that are best suited to meet your needs.

Range of Products

A good supplier will offer a diverse range of mini assembly machines tailored to different applications. Whether you need machines for small-scale electronics assembly or more complex manufacturing tasks, the supplier should have a variety of options to choose from.

Customization Options

No two manufacturing processes are identical. A reputable supplier will offer customization options to modify the machine’s specifications according to your specific production requirements.

After-Sales Support

Once the machine is purchased, a reliable supplier will offer after-sales support, including installation, training, and maintenance services. This is crucial in ensuring that your assembly machine operates at optimal efficiency throughout its lifespan.

Cost and Warranty

Pricing is always a consideration when investing in machinery. While it’s tempting to go for the lowest price, consider the long-term benefits of investing in a high-quality machine. Check if the supplier offers a warranty and what it covers. A good warranty can save you a lot of money in repairs and replacements in the long run.

Industries Benefiting from Mini Assembly Machines

Mini assembly machines have applications in several industries, each benefiting from the machine’s efficiency and precision. Here’s a look at some of the industries where these machines are making a significant impact:

Electronics Manufacturing

The electronics industry relies heavily on precision, given the tiny components used in devices such as smartphones, tablets, and laptops. Mini assembly machines are ideal for assembling these delicate components with minimal risk of damage. Suppliers specializing in electronics assembly machines ensure that their products meet the strict quality requirements of the industry.

Automotive Parts Assembly

Automotive manufacturers often use mini assembly machines for tasks that involve small parts, such as sensors, wiring, and other intricate components. The high speed and accuracy of these machines make them invaluable in automotive assembly lines, where precision is critical.

Medical Device Manufacturing

The medical field requires the assembly of small, precise devices such as hearing aids, pacemakers, and diagnostic equipment. Mini assembly machines ensure the accurate assembly of these critical components, enhancing product reliability and safety.

Home Appliance Assembly

From kitchen gadgets to personal care appliances, the home appliance industry also benefits from mini assembly machines. Their ability to work efficiently in smaller spaces makes them ideal for assembling intricate parts of household products.

The Future of Mini Assembly Machines

As technology continues to evolve, mini assembly machines are becoming more advanced. Automation, AI, and machine learning are being integrated into these machines, enhancing their functionality and making them even more efficient. Suppliers who stay ahead of these technological advancements will be the ones driving the future of manufacturing.

Trends Shaping the Mini Assembly Machine Industry

Integration with IoT

Many mini assembly machines are now equipped with sensors and connectivity features that allow them to communicate with other machines on the production line. This enables real-time monitoring and adjustments, improving the overall efficiency of the assembly process.

AI-Powered Assembly

Artificial intelligence is being integrated into mini assembly machines to enhance precision and decision-making. AI algorithms can predict machine maintenance needs and even optimize assembly processes based on data analysis.

Sustainability in Manufacturing

As industries focus more on sustainability, mini assembly machine suppliers are also contributing by producing energy-efficient machines. The trend is toward machines that consume less power and produce less waste, helping companies meet their sustainability goals.

Wholesale Mini Trigger Dropper Assembly Machine: A Specialty Option

For those in need of specialized equipment, the wholesale mini trigger dropper assembly machine is an excellent option. Designed for assembling trigger droppers used in cosmetics, pharmaceuticals, and other liquid dispensing products, this machine offers speed, precision, and reliability. Suppliers offering such machines cater to businesses requiring bulk assembly solutions, ensuring the equipment meets the high standards of quality expected in these industries.

Conclusion

Choosing the right mini assembly machine supplier can greatly influence the efficiency and profitability of your manufacturing process. From offering a wide range of machines to providing essential after-sales support, a good supplier ensures that your production line runs seamlessly. As industries evolve, so too will the technology behind mini assembly machines, with AI, IoT, and sustainability playing major roles in shaping the future.

By focusing on these trends and selecting a reputable supplier, businesses can ensure they are well-equipped to meet the demands of modern manufacturing. Whether you're in electronics, automotive, or home appliances, the right mini assembly machine supplier will help you stay competitive in today's ever-changing industrial landscape.