Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Lotion Pump Mould Manufacturers: Driving Innovation in the Packaging Industry

The role of lotion pump mould manufacturers is pivotal in the modern packaging industry, particularly for cosmetics, personal care, and household products. These manufacturers are the backbone of the pump industry, shaping the components that ensure precise liquid dispensing. With the rising demand for innovative and eco-friendly packaging solutions, lotion pump mould manufacturers are stepping up their game to cater to brands globally. This blog will explore how these manufacturers are contributing to the packaging landscape, what makes them stand out, and the key factors to consider when choosing a reliable manufacturer.

The Importance of Lotion Pump Mould Manufacturers

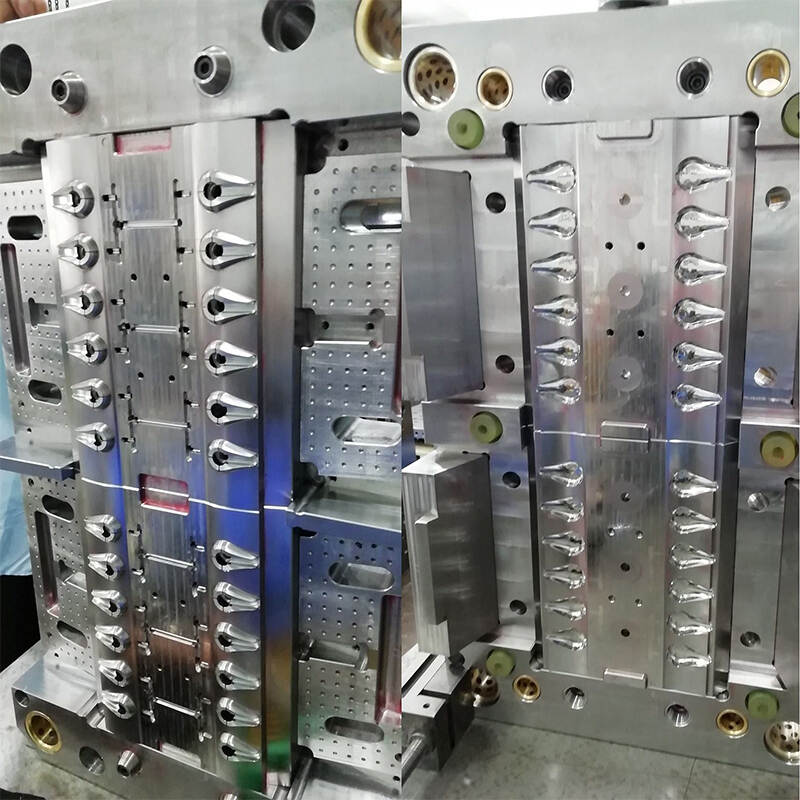

Lotion pumps have become a staple in liquid dispensing solutions, found in a variety of products ranging from shampoos and lotions to cleaning solutions and oils. Behind every lotion pump is a well-designed mould, crafted by expert manufacturers who ensure precision and durability. Lotion pump mould manufacturers play a critical role in creating the high-quality moulds that drive efficient and reliable pump production. They combine cutting-edge technology with industry expertise to deliver moulds that meet the specific needs of brands and consumers alike.

For companies seeking to establish a unique identity in a competitive market, the collaboration with a reputable lotion pump mould manufacturer can be the key to success. From providing tailored designs to ensuring the highest manufacturing standards, these companies are vital in maintaining consistency and quality in packaging.

Key Features of a Reputable Lotion Pump Mould Manufacturer

When selecting a lotion pump mould manufacturer, several factors should be considered. Here are some key features that differentiate leading manufacturers from the rest:

Precision and Accuracy: The design and functionality of a lotion pump depend heavily on the precision of the mould. Manufacturers use advanced machinery to create intricate and precise moulds that ensure each pump is efficient and reliable.

Customization Options: Leading manufacturers offer customization options for their clients. Whether it’s a unique pump design, specific material preferences, or brand-specific aesthetics, customization allows companies to stand out in the marketplace.

Durable and Long-lasting Moulds: High-quality materials and engineering techniques are crucial in producing durable moulds that can withstand repeated use in the production line.

Technological Advancements: Top lotion pump mould manufacturers stay ahead of the curve by adopting the latest technologies in mould design and manufacturing, ensuring greater accuracy and efficiency.

Cost-effectiveness: While quality is paramount, affordability is also a key consideration. Reliable manufacturers strike a balance between delivering quality moulds at competitive prices, helping brands manage their budgets effectively.

Benefits of Working with an Established Lotion Pump Mould Manufacturer

Partnering with a trusted manufacturer provides several advantages:

Streamlined Production: Established manufacturers have optimized production processes that ensure timely and efficient delivery of moulds. This helps brands avoid production delays and maintain consistent supply chains.

Quality Assurance: Experienced manufacturers implement strict quality control measures throughout the production process. This minimizes defects and ensures the pumps produced meet industry standards.

Expert Guidance: With years of experience in the industry, reputable manufacturers can offer valuable insights and guidance to help brands make informed decisions regarding pump design, materials, and functionality.

Innovation in Lotion Pump Mould Manufacturing

Innovation is a driving force in the packaging industry, and lotion pump mould manufacturers are no exception. The demand for eco-friendly and sustainable packaging solutions is pushing manufacturers to develop new materials and designs that reduce environmental impact.

Sustainability Initiatives: Many manufacturers are exploring the use of biodegradable and recyclable materials for their moulds and pumps. This trend is not only reducing the carbon footprint of the packaging industry but also meeting the growing consumer demand for environmentally responsible products.

Smart Packaging Solutions: The incorporation of smart technology into packaging is becoming more prevalent, and pump manufacturers are exploring ways to integrate smart features into their designs. This includes pumps that track usage, reduce product waste, or dispense precise amounts of liquid with each use.

Lightweight and Efficient Designs: Reducing material use without compromising functionality is another area where manufacturers are innovating. Lightweight lotion pumps not only reduce shipping costs but also contribute to reducing plastic waste.

Choosing the Right Lotion Pump Mould Manufacturer

When looking for the right lotion pump mould manufacturer, businesses should evaluate potential partners based on their track record, technological capabilities, and customer service. Here are some tips for selecting a reliable manufacturer:

Evaluate Their Portfolio: Review the manufacturer's portfolio to assess the quality and diversity of their past projects. This will give you a sense of their capabilities and the type of clients they have worked with.

Check Certifications and Standards: Ensure that the manufacturer adheres to industry standards and holds relevant certifications. This is important for maintaining quality control and ensuring that your products meet regulatory requirements.

Consider Lead Times and Flexibility: Manufacturers should be able to accommodate your production timelines and adjust to any changes in order quantities. Flexibility and reliability are key to ensuring smooth operations.

Ask About R&D Capabilities: Manufacturers that invest in research and development are likely to be more innovative and adaptable. R&D capabilities can be a game-changer when looking for unique packaging solutions.

Cost Transparency: Look for manufacturers who provide clear and transparent pricing. Hidden fees can quickly eat into your budget, so it's important to work with a manufacturer who offers straightforward pricing.

Industry Trends in Lotion Pump Manufacturing

The global packaging industry is evolving, and lotion pump manufacturers are continuously adapting to these changes. Key trends shaping the industry include:

Sustainability: As mentioned earlier, sustainability is a top priority for many brands. Lotion pump manufacturers are innovating to produce moulds that accommodate eco-friendly materials and designs.

Customization: With the rise of e-commerce and digital marketing, brands are increasingly seeking unique packaging solutions that set them apart from the competition. Customized lotion pumps are becoming a popular choice for brands looking to create a strong visual identity.

Automation in Manufacturing: Automation technologies are enhancing the efficiency of mould production, leading to faster turnaround times and reduced labor costs. This is a trend that will continue to grow as manufacturers invest in advanced machinery and automation systems.

Conclusion

The role of lotion pump mould manufacturers in the packaging industry is crucial. They not only ensure the efficient production of high-quality lotion pumps but also drive innovation in design, sustainability, and functionality. As the demand for unique and eco-friendly packaging grows, these manufacturers will continue to play a key role in shaping the future of packaging solutions.

Whether you are a brand looking for a reliable lotion pump mould factory or a company aiming to explore cutting-edge pump designs, choosing the right manufacturer can make all the difference in achieving your packaging goals. By focusing on precision, customization, and sustainability, lotion pump mould manufacturers are leading the way in delivering innovative and practical packaging solutions.