Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

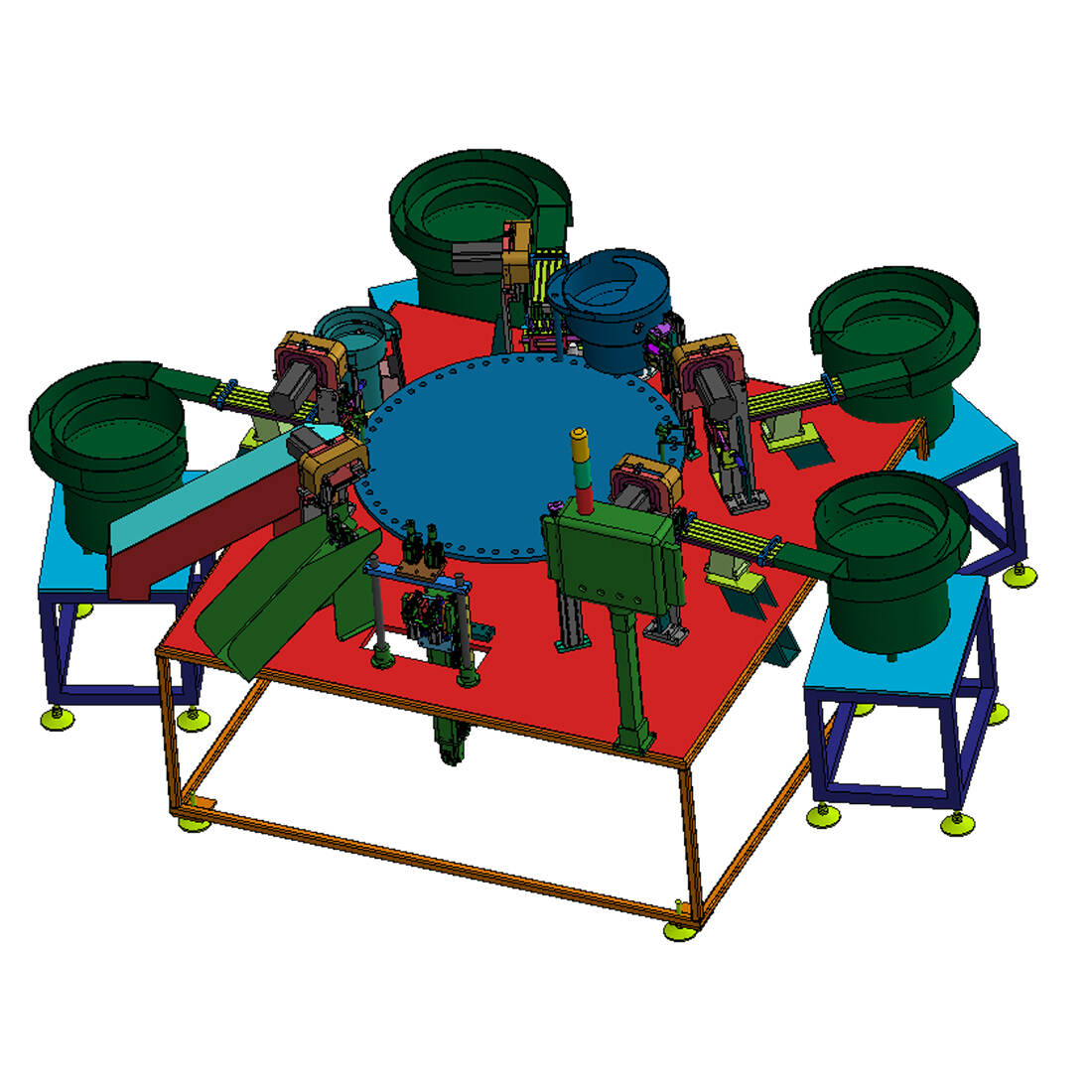

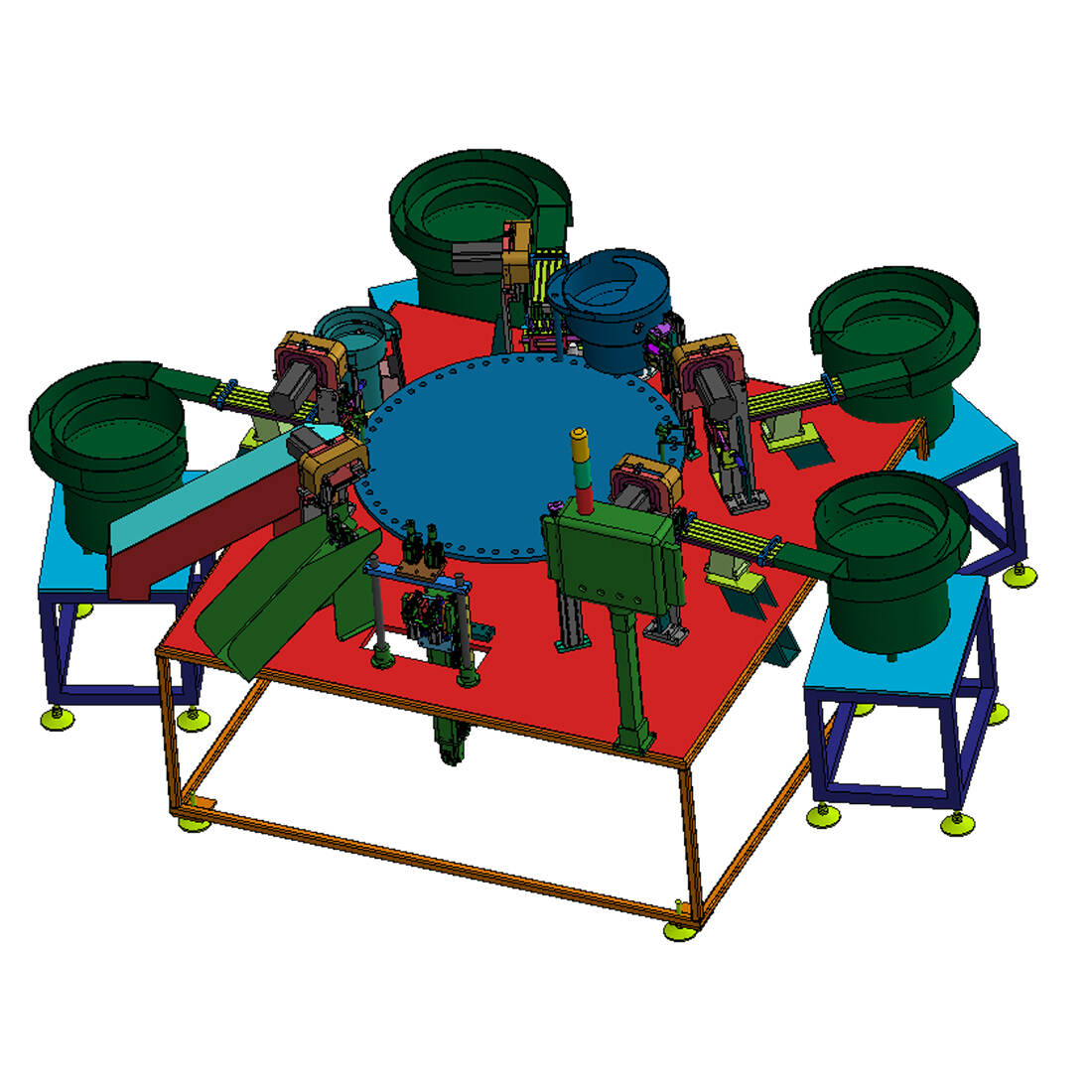

The Power of Mini Assembly Machines: Revolutionizing Manufacturing

In today’s fast-paced world, the demand for high-efficiency manufacturing solutions is rising. The need for cost-effective solutions has never been greater. One solution has captured global industrial attention. That solution is the mini assembly machine. These machines are compact in size. However, they deliver exceptional performance. They also offer remarkable precision. Their adaptability is another key strength. Manufacturers are exploring innovative methods to meet production demands. As a result, mini assembly machines are becoming popular across sectors. Industries like electronics and automotive are adopting them. Other sectors are following suit.

In this blog post, we will explore the benefits of these machines. We will analyze their features. We will also discuss the trend of mini assembly machine exports. Manufacturers aiming to optimize production should pay attention. Business partners seeking new opportunities must understand their value.

What is a Mini Assembly Machine?

A mini assembly machine is a compact automated device. It performs tasks like assembling small components. It tests products. It packages items for distribution. Traditional assembly lines are large. In contrast, these machines are space-efficient. They are cost-effective. They are flexible. They ensure high precision in assembly. They can operate nonstop. This reduces manual labor needs. Consistency and quality are maintained.

These machines suit small-scale production runs. They are ideal for space-limited industries. Electronics is a key sector. Medical devices are another. Consumer goods also benefit. Their versatility drives popularity. Businesses can scale production without sacrificing quality. They avoid excessive costs.

The Advantages of Mini Assembly Machines

1. Space-Efficiency

Mini assembly machines have compact designs. Traditional lines require large floors. Complex setups are common. Maintenance is expensive and time-consuming. Mini machines occupy minimal space. This suits small-to-medium manufacturers. Limited floor space is no longer a barrier. Production areas become optimized. Resources are allocated effectively.

2. Cost-Effectiveness

These machines are affordable. Their smaller size reduces costs. Streamlined designs enhance affordability. They are ideal for SMEs. Budget constraints limit access to large assembly lines. Operational costs are lower. Energy consumption decreases. Maintenance expenses drop. Long-term savings accumulate.

3. High Precision and Reliability

Mini machines prioritize precision. They place tiny components accurately. They tighten screws consistently. They test products reliably. Electronics demand zero errors. Errors cause product failures. Advanced sensors are integrated. Robotic arms enhance operations. AI-driven controls minimize human error.

4. Flexibility and Customization

Flexibility defines these machines. They adapt to specific production needs. Assembly speeds can be adjusted. Tools are interchangeable. Programming accommodates diverse tasks. Customization meets unique requirements. Businesses evolve over time. Machines adapt to new products. Production changes are manageable.

The Growing Trend of Mini Assembly Machine Export

Global industries are evolving. Demand for mini assembly machine exports is surging. Manufacturers seek reliable suppliers. Quality is a priority. Quick delivery times matter. Competitive pricing is essential. Advanced manufacturing hubs export globally.

Global Demand for Mini Assembly Machines

Demand is rising worldwide. Emerging markets embrace automation. Asia adopts this technology rapidly. Europe follows the trend. North America recognizes its advantages. Efficient solutions are sought. Affordability drives competitiveness.

Businesses seek productivity boosts. Cost reduction is critical. Export markets for these machines are booming. Consumer electronics drive demand. Automotive sectors contribute. Healthcare industries rely on them. Customization strengthens global appeal. After-sales support adds value.

Why Consider Exporting Mini Assembly Machines?

Exporting offers expansion opportunities. Global automation demand creates markets. International revenue streams grow. Partnerships form with manufacturers. Reputations enhance globally.

Strategic collaborations emerge. Suppliers provide innovative solutions. High-quality machines attract partners. Long-term relationships drive growth. Innovation accelerates through exports.

Mini Assembly Machines in Various Industries

Electronics Manufacturing

Precision and speed dominate electronics. Mini machines assemble circuit boards. They handle connectors and semiconductors. Automation ensures accuracy. Consumer demand for electronics grows. Production costs decrease. Operations streamline.

Medical Devices

Regulations are strict in healthcare. Mini machines produce medical devices. Sensors and diagnostic tools are assembled. Surgical instruments meet safety standards. Precision ensures compliance. Reliability is non-negotiable.

Automotive Industry

Large-scale lines dominate automotive. However, mini machines assemble small parts. Interior components are handled. Electrical systems benefit. Industry standards are met.

Consumer Goods

Household appliances utilize automation. Toys are assembled efficiently. Testing and packaging accelerate. Product consistency improves. Competitive pricing is achievable.

Future Outlook: Mini Assembly Machines and Industry 4.0

Industry 4.0 integrates IoT and AI. Machine learning transforms manufacturing. Mini machines lead this revolution. They communicate with production devices. Data enables real-time analysis. Maintenance predictions become possible.

Future machines will be smarter. Efficiency will increase. Adaptability will expand. Automation adoption will grow. Global production lines will revolutionize.

Conclusion: Why Partner with Us for Your Mini Assembly Machine Needs

We delivers quality automation solutions. We are trusted manufacturers. We export cutting-edge mini assembly machines. Productivity enhances for clients. Costs reduce effectively. Quality remains unmatched.

We serve diverse industries. Electronics and medical sectors rely on us. Customization meets client needs. Export experience ensures timely delivery. Pricing is competitive. Customer service excels.

Modern manufacturing demands the right tools. Partner with us for advanced solutions. Space efficiency is guaranteed. Cost-effectiveness is assured. Elevate your business today.