Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The Magic of Mist Sprayer Assembly Machines: Revolutionizing the Beauty and Health Industry

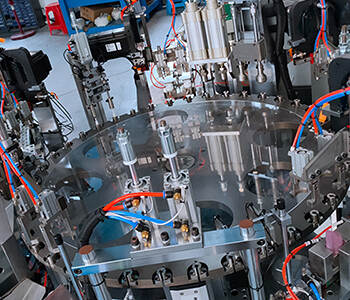

In a world where beauty and personal care products are in high demand, the production processes behind these products often go unnoticed. One of the most fascinating components in this process is the mist sprayer assembly machine. This device plays a crucial role in ensuring that mist sprayers—whether for perfumes, skincare products, or cleaning solutions—are produced with precision and efficiency. In this blog, we will explore what a mist sprayer assembly machine is, how it works, and why it is so important in the production of everyday items we often take for granted.

What is a Mist Sprayer Assembly Machine?

A mist sprayer assembly machine is a specialized piece of equipment used in the manufacturing process of mist sprayers. Mist sprayers, which are commonly seen in products like perfumes, deodorants, air fresheners, and skincare products, create a fine, uniform spray when activated. These sprayers typically consist of several small parts, including the nozzle, pump, spring, and the straw that connects the pump to the liquid in the bottle.

The mist sprayer assembly machine automates the process of assembling these tiny, delicate parts into a fully functional sprayer. This type of machine is designed to increase the speed, accuracy, and consistency of production, which is especially important in industries where large volumes of products are needed, such as in cosmetics or household goods.

How Does a Mist Sprayer Assembly Machine Work?

A mist sprayer assembly machine might seem complex, but its functionality is straightforward. Let’s break it down:

Feeding and Loading

The first step in the assembly process is feeding the individual components (like the nozzle, straw, and pump) into the machine. In some cases, these parts may come in bulk, and the assembly machine uses various mechanisms—such as vibratory feeders or conveyor belts—to position each piece correctly.

Automated Assembly

Once the parts are positioned, the machine uses robotic arms, pneumatic tools, or automated grippers to assemble the mist sprayer. For example, the nozzle is attached to the pump, the pump is fitted onto the bottle, and the straw is placed inside the pump, ensuring everything is aligned perfectly.

Testing and Quality Control

After assembly, many mist sprayer machines are equipped with testing systems that ensure the sprayers work correctly. These machines can check for leaks, measure the spray distance, and ensure that each sprayer produces a fine, even mist. This is essential for maintaining product quality, especially when dealing with beauty and skincare items that require precise dispensing.

Packaging

Finally, the assembled mist sprayers are ready for packaging. Some mist sprayer assembly machines also have integrated packaging systems, allowing the final product to be placed in boxes or containers for shipping. This stage may involve another round of inspection to make sure everything is perfect before the product reaches the market.

Why is the Mist Sprayer Assembly Machine So Important?

Mist sprayers might seem like simple tools, but their creation requires attention to detail. The mist that is dispensed must be consistent, and the sprayer must function smoothly each time it’s used. Here’s why the mist sprayer assembly machine is so essential to this process:

1. Efficiency and Speed

One of the biggest advantages of using an automated assembly machine is efficiency. Assembly machines can work much faster than human hands, producing hundreds or even thousands of mist sprayers in an hour. This is crucial for large-scale production, where companies need to meet high demand for their products.

Without the mist sprayer assembly machine, the production process would be slower and more labor-intensive. Human workers would have to manually assemble each component, which could lead to inconsistencies or errors in the final product.

2. Precision and Accuracy

Creating a mist sprayer requires precision. Each part of the sprayer must be positioned and assembled with care. The sprayer must function correctly to ensure that it produces a fine mist, not a stream of liquid or a clogged nozzle.

A mist sprayer assembly machine ensures that each component is assembled with the same level of accuracy every time. This consistency is vital for maintaining the high quality of products like perfumes, facial sprays, or even cleaning products, where the user experience is heavily influenced by how the product is dispensed.

3. Cost-Effectiveness

While there is an upfront cost in purchasing and setting up a mist sprayer assembly machine, it can be much more cost-effective in the long run. By automating the assembly process, companies can reduce labor costs, minimize errors, and increase output. The ability to produce large quantities of mist sprayers efficiently translates to cost savings that can benefit both the manufacturer and the consumer.

4. Improved Quality Control

In industries like cosmetics and personal care, quality control is critical. A faulty mist sprayer can lead to product waste, customer dissatisfaction, and even damage a brand's reputation. Mist sprayer assembly machines often come with built-in quality control features, such as leak detection and spray performance tests. These automated tests help ensure that every sprayer functions as intended, leading to fewer defects and higher customer satisfaction.

5. Customization and Versatility

Mist sprayer assembly machines are not one-size-fits-all. Many modern machines are versatile and can be adjusted to handle different types of mist sprayers, whether they are for large bottles or small travel-sized containers. This flexibility allows manufacturers to customize their production lines based on the specific needs of their products.

For example, some machines are designed to handle sprayers with specialized nozzles, while others can accommodate various bottle sizes. This versatility ensures that companies can easily switch between different product lines without needing to invest in entirely new machinery.

Real-World Applications of Mist Sprayer Assembly Machines

Mist sprayer assembly machines are found in many industries beyond cosmetics and personal care. Let’s take a look at some real-world applications:

1. Cosmetics and Skincare

The most common use for mist sprayers is in the beauty and skincare industry. Products like facial mists, perfumes, and body sprays rely on mist sprayers to deliver a fine, even spray. Mist sprayer assembly machines ensure that these sprayers are assembled correctly so that they can perform well throughout their lifespan.

2. Household Products

Mist sprayers are also used in a wide range of household products, including air fresheners, cleaning solutions, and disinfectants. In this case, the sprayer needs to deliver a fine mist that covers a large area, ensuring that the cleaning product or air freshener is evenly distributed.

3. Industrial Applications

Mist sprayers are also used in certain industrial settings, such as for lubricants, solvents, and other chemicals. These sprayers are often more robust and designed for heavier-duty use, but they still rely on precise assembly to function efficiently.

4. Health and Wellness Products

Products like sanitizers, sprays for disinfecting hands or surfaces, and essential oils also rely on mist sprayers. Especially in the wake of global health challenges, the demand for high-quality mist sprayers in the healthcare sector has increased, making the role of the mist sprayer assembly machine even more important.

Conclusion

The mist sprayer assembly machine is a marvel of modern manufacturing. By automating the assembly of mist sprayers, these machines help ensure efficiency, precision, and quality control in industries ranging from cosmetics to healthcare. Their role is not only to speed up production but also to make sure that the final product performs as expected every time it is used.

As the demand for personal care, cleaning, and wellness products continues to rise, the importance of mist sprayer assembly machines will only increase. These machines are helping brands meet the high expectations of consumers and deliver products that are both functional and high-quality. So, the next time you use a perfume or clean your house with a fresh spray, remember that a mist sprayer assembly machine played a key role in bringing that product to life!