Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The Importance of Ferrule Assembly Machines in Modern Manufacturing: A Look at the Role of Ferrule Assembly Machine Manufacturers

In the vast world of industrial automation, few pieces of equipment are as integral to the production of high-quality electronic components as ferrule assembly machines. Whether in telecommunications, automotive industries, or medical equipment manufacturing, ferrules play a crucial role in ensuring safe and reliable connections. This blog explores the significance of ferrule assembly machines, shedding light on the technology behind them, their various applications, and why choosing the right ferrule assembly machine manufacturer is key to the success of a manufacturing process.

What is a Ferrule?

Before diving into the intricacies of ferrule assembly machines, it’s important to first understand what a ferrule is. A ferrule is a small but essential component typically made from metal, such as brass or stainless steel, and it is used to secure and protect the end of a wire or cable. Ferrules are commonly used in electrical connectors and cables to create a durable and safe connection between the conductor and the terminal.

Ferrules are not just an afterthought; they ensure a stable electrical connection, enhance the longevity of cables, and prevent wires from fraying or becoming damaged. They are integral to the production of high-performance cables used in everything from home appliances to high-tech machinery.

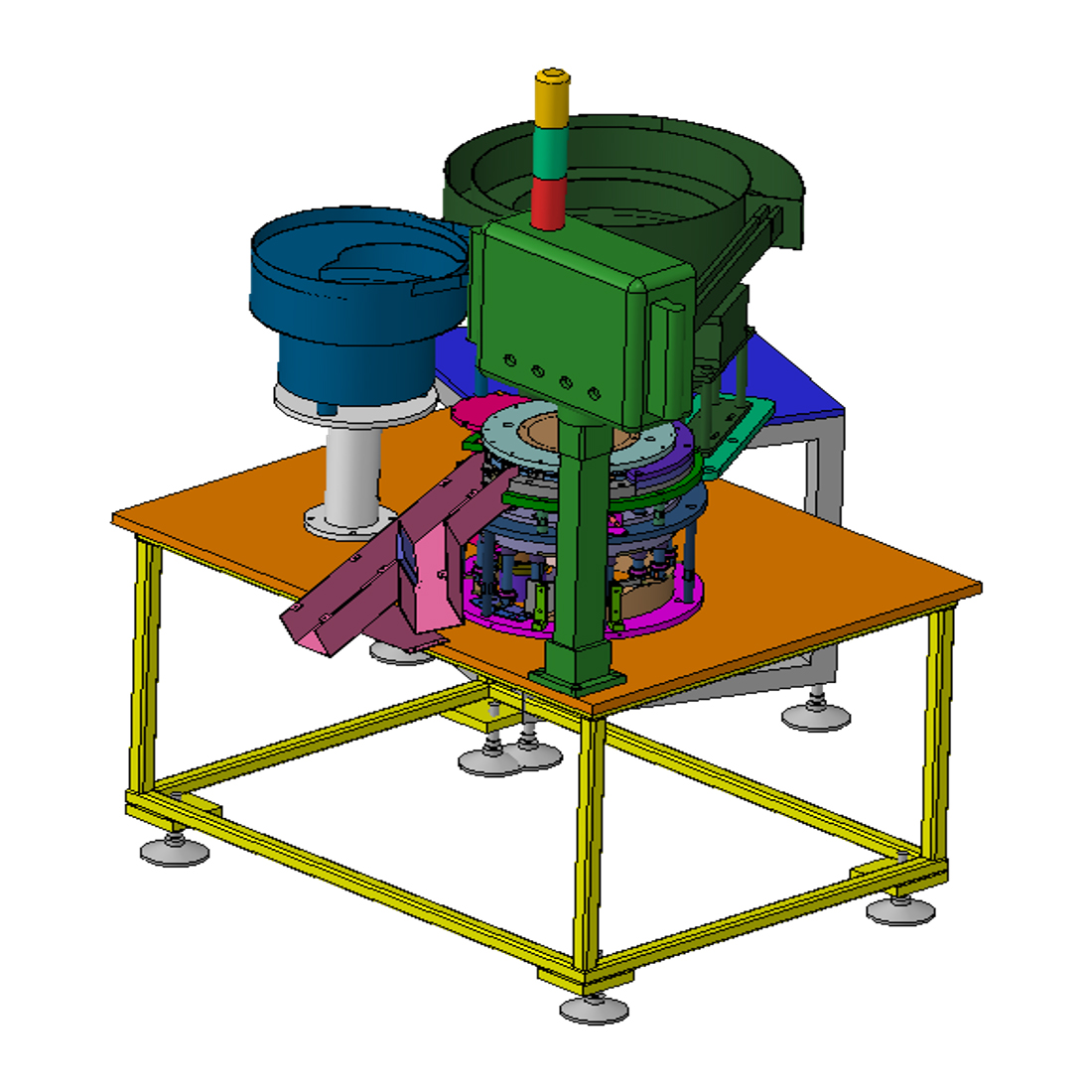

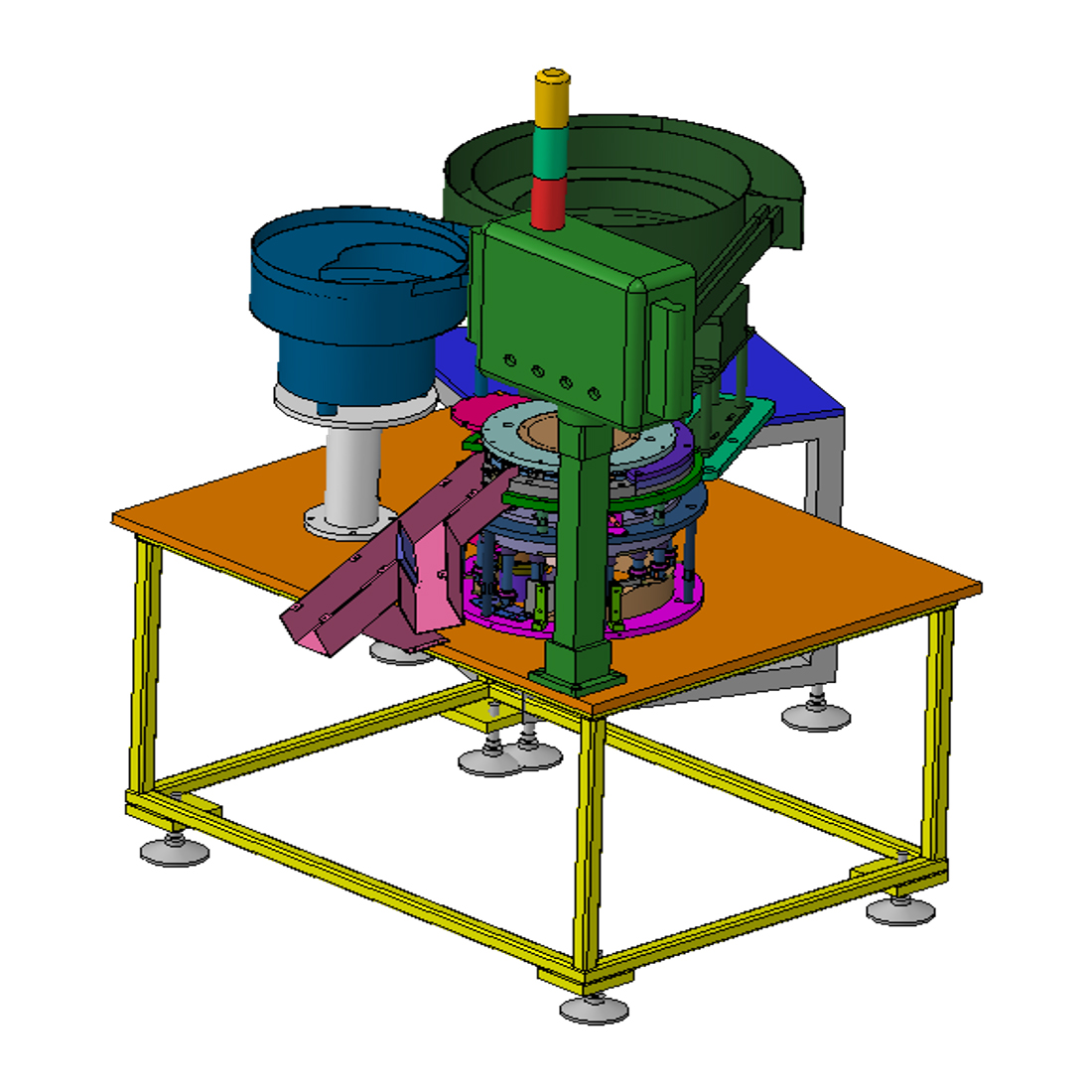

The Role of Ferrule Assembly Machines

The process of assembling ferrules involves precision and efficiency, and that’s where ferrule assembly machines come into play. These specialized machines are designed to automatically crimp or attach ferrules to the ends of wires or cables. Ferrule assembly machines streamline what would otherwise be a labor-intensive, manual process, allowing manufacturers to achieve consistency, speed, and precision.

The ferrule assembly machine performs several important tasks:

Ferrule Insertion: The machine automatically places a ferrule over the wire, ensuring that it is aligned correctly. This step is critical as improper alignment can result in weak or faulty connections.

Crimping or Compression: Once the ferrule is in place, the machine uses pressure to crimp the ferrule onto the wire, securing it in place. The crimping process must be precise to ensure a tight and reliable connection that can withstand the stresses of daily use.

Quality Control: Most ferrule assembly machines are equipped with sensors and vision systems to verify the quality of each ferrule attached to the wire. This ensures that any defective or improperly installed ferrules are identified and removed from the production line before they can cause problems downstream.

Automation and Speed: With the use of ferrule assembly machines, manufacturers can automate the process of ferrule installation, drastically increasing production speed and reducing labor costs.

Why are Ferrule Assembly Machines Important?

1. Accuracy and Consistency

The most critical advantage of using a ferrule assembly machine is its ability to deliver high precision and consistency. In many industries, especially those where electrical components are involved, even small deviations can lead to failures or malfunctions. Manual assembly often introduces the risk of human error, but automated ferrule assembly machines eliminate this concern, ensuring every ferrule is securely and precisely crimped onto the wire.

2. Increased Productivity

Ferrule assembly machines are designed for speed. By automating the process, manufacturers can significantly increase their production output without compromising on quality. Machines can operate 24/7, with minimal downtime, making them an invaluable asset for manufacturers looking to meet large-scale production demands.

3. Improved Safety and Reliability

A properly assembled ferrule ensures a safe electrical connection, reducing the risk of short circuits, wire damage, or electrical fires. Ferrule assembly machines help maintain high standards of quality, leading to safer products that are more reliable and durable.

4. Cost Efficiency

While the initial investment in a ferrule assembly machine can be high, the long-term savings are substantial. Automation reduces the need for manual labor, speeds up production, and decreases the likelihood of defective products, all of which contribute to cost savings. Additionally, by reducing the chances of human error, manufacturers can avoid costly recalls or product failures.

Applications of Ferrule Assembly Machines

Ferrule assembly machines are used in a wide range of industries, from consumer electronics to industrial machinery. Let’s explore some of the most common applications:

1. Telecommunications

In the telecommunications industry, ferrules are used in fiber optic cables, which are critical for high-speed internet and communication networks. Ferrule assembly machines ensure that the ferrules are accurately and securely attached to the fiber optic cables, guaranteeing the high-performance standards required for telecommunications infrastructure.

2. Automotive Industry

The automotive industry relies heavily on high-quality electrical components for the operation of modern vehicles. Ferrule assembly machines are used to attach ferrules to various cables within cars, trucks, and other vehicles. These cables connect everything from the engine components to the vehicle’s electrical systems, and ensuring these connections are secure is essential for vehicle safety and performance.

3. Medical Devices

In the medical field, the reliability of electrical connections in medical devices is a matter of life and death. Ferrules are used in many medical instruments to maintain reliable electrical connections, ensuring that devices function correctly. Ferrule assembly machines are employed to maintain the high-quality standards necessary for medical device manufacturing.

4. Industrial Machinery

Heavy-duty industrial machinery, such as manufacturing robots, conveyor belts, and CNC machines, often relies on complex wiring systems. Ferrule assembly machines are essential for creating secure and durable connections within these systems, which are critical for machinery performance.

Choosing the Right Ferrule Assembly Machine Manufacturer

When it comes to selecting a ferrule assembly machine, one of the most important factors to consider is the manufacturer. The right ferrule assembly machine manufacturer can make a significant difference in terms of machine quality, efficiency, and reliability.

Here are some factors to keep in mind when selecting a ferrule assembly machine manufacturer:

1. Experience and Reputation

An experienced ferrule assembly machine manufacturer is more likely to offer high-quality machines that are tested and proven in real-world manufacturing environments. Look for manufacturers with a strong reputation in the industry, as they will have a history of delivering reliable, durable machines.

2. Customization Options

Every manufacturing line is different, and flexibility is key when selecting a ferrule assembly machine. A good manufacturer will offer customization options to fit the specific needs of your production line. Whether you need a machine that handles different types of ferrules or one that integrates with your existing automated systems, customization options can ensure a smoother workflow.

3. Technical Support and Service

A reliable ferrule assembly machine manufacturer should provide strong customer service and technical support. This is essential for ensuring your machine continues to operate efficiently and that any issues are quickly resolved. Look for manufacturers who offer training for operators, as well as ongoing support for troubleshooting and maintenance.

4. Innovation and Technology

The best ferrule assembly machine manufacturers are those who continually invest in research and development to improve their machines. New technologies such as AI-driven quality control, faster crimping processes, and automated diagnostics can make a big difference in the efficiency and reliability of your ferrule assembly operations.

5. Cost-Effectiveness

While it’s important not to compromise on quality, the cost of the machine is also a significant factor. A good ferrule assembly machine manufacturer should offer machines that provide value for money while still meeting your production requirements.

Conclusion

Ferrule assembly machines are indispensable tools in modern manufacturing, enabling industries to produce high-quality, reliable products at scale. From telecommunications to automotive manufacturing, ferrules play a crucial role in ensuring the safety and efficiency of electrical systems. Choosing the right ferrule assembly machine manufacturer is key to maintaining high production standards and staying competitive in today’s fast-paced industrial environment.

By embracing automation through ferrule assembly machines, manufacturers can ensure precision, reduce costs, and improve product safety and reliability. With the right equipment and manufacturer partnership, businesses can streamline their production processes, enhance product quality, and meet the ever-growing demand for reliable electrical components in various industries.

If you’re looking to invest in ferrule assembly machines, make sure to choose a manufacturer with a proven track record, and one that offers innovative solutions to meet the specific needs of your production line. The right machine can make all the difference in helping your business succeed in the highly competitive world of manufacturing.