Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The Growing Importance of Mini Assembly Machines in Modern Manufacturing

In today's fast-paced and ever-evolving manufacturing world, the demand for efficient, precise, and cost-effective solutions has never been higher. One area where this demand is especially evident is in assembly lines, where speed and accuracy are critical to meeting production targets. One technology that has been making waves in this regard is the mini assembly machine. These compact yet powerful machines are revolutionizing the way products are assembled, offering manufacturers a way to improve productivity without sacrificing quality. In this blog, we'll take a closer look at what mini assembly machines are, why they are becoming increasingly popular, and how selecting the right mini assembly machine supplier can make all the difference.

What is a Mini Assembly Machine?

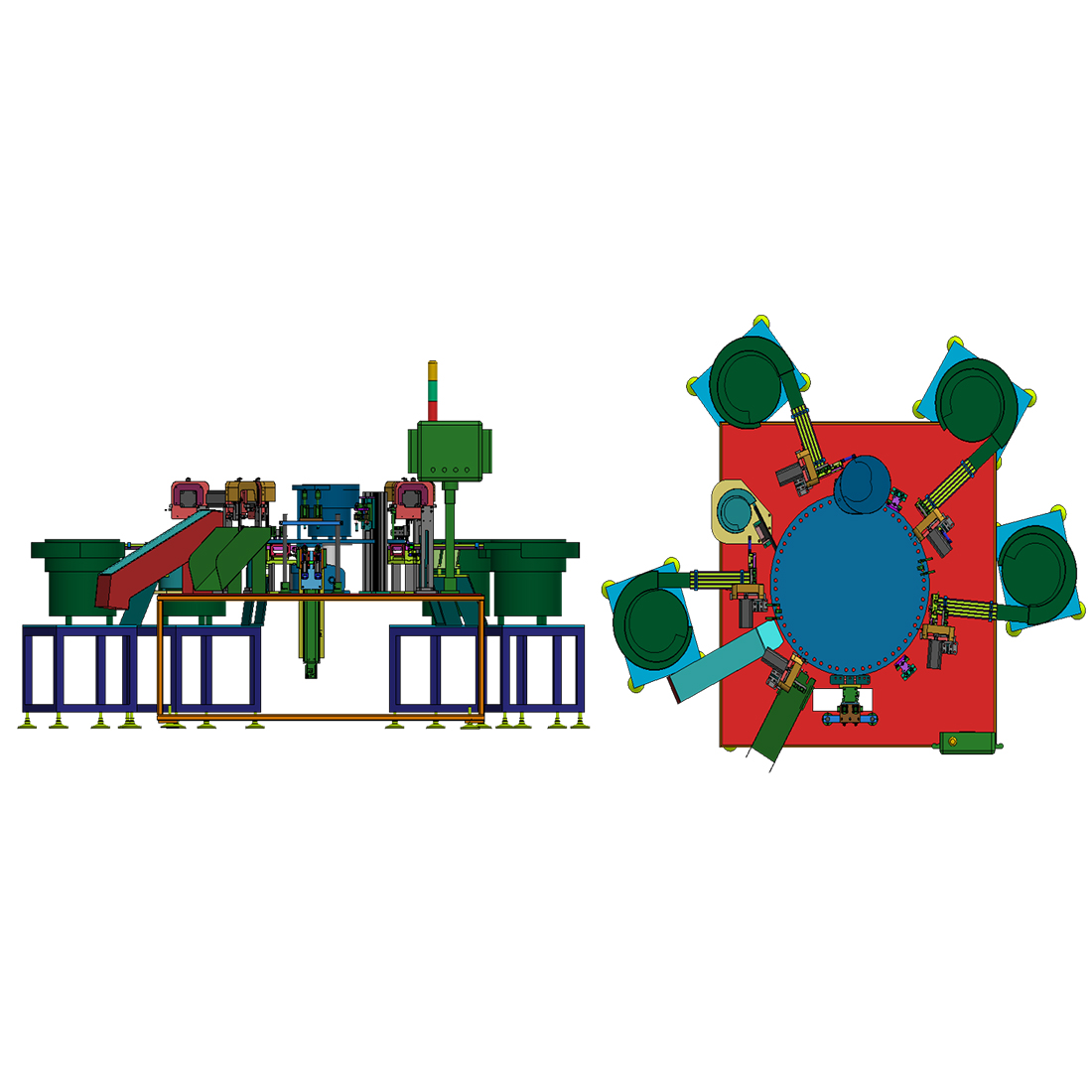

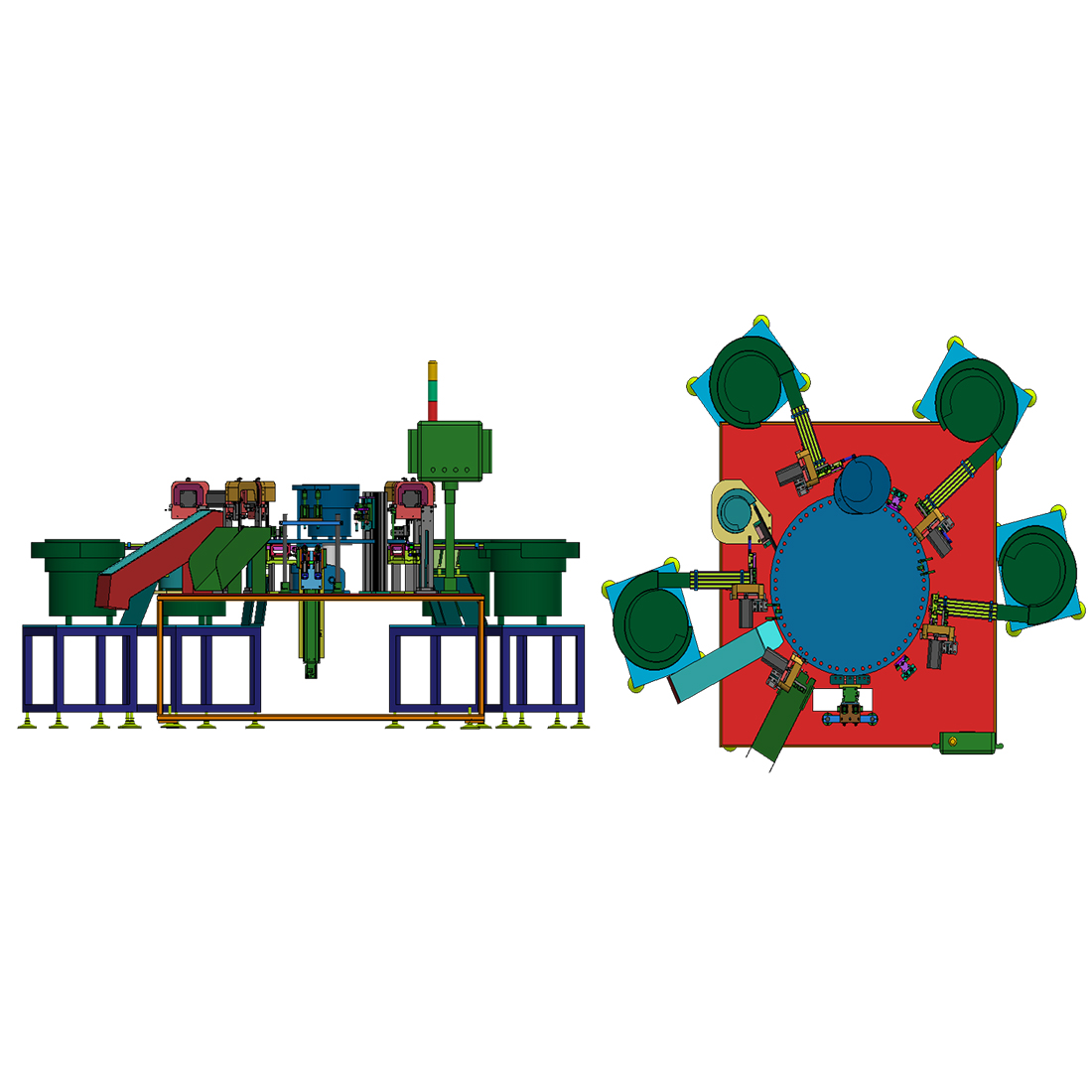

A mini assembly machine is a small-scale, automated system used to assemble components or parts of a product. Unlike larger, traditional assembly machines that can handle high-volume production, mini assembly machines are designed for smaller tasks or smaller batches of products. They are often used in industries where space is limited, and precision is key, such as electronics, automotive, medical devices, and consumer goods.

These machines can perform a wide range of functions, from simple tasks like inserting screws or placing components on a circuit board, to more complex tasks like testing and quality inspection. Despite their small size, they are incredibly versatile and can be customized to meet the unique needs of each manufacturing process.

The Advantages of Mini Assembly Machines

1. Compact and Space-Saving Design

One of the most significant advantages of mini assembly machines is their compact size. Unlike large, bulky machines that require significant floor space, mini machines can fit into smaller workspaces. This makes them ideal for manufacturers with limited space or those who need to optimize their factory layout.

In addition to saving space, the small footprint of mini assembly machines also reduces overhead costs associated with real estate, utility bills, and maintenance. For small and medium-sized enterprises (SMEs), this can be a game-changer, allowing them to invest in automation without the need for a massive production facility.

2. Increased Precision and Consistency

Mini assembly machines are often built to handle delicate and intricate tasks that require a high level of precision. Whether it's assembling tiny electronic components or placing microchips onto circuit boards, these machines are capable of delivering consistent results with minimal errors. This level of accuracy ensures that products meet strict quality control standards, reducing the likelihood of defects and costly rework.

In industries like electronics and medical devices, where precision is paramount, the ability to maintain consistent quality can set a manufacturer apart from competitors. With mini assembly machines, companies can achieve the high levels of accuracy that customers demand.

3. Enhanced Flexibility and Customization

Another significant advantage of mini assembly machines is their flexibility. These machines can be easily adapted to different types of assembly tasks by changing out components, tools, or software. For example, a mini assembly machine designed for assembling smartphone parts can be reprogrammed or modified to handle the assembly of a completely different product, such as a medical device or a consumer appliance.

This level of customization makes mini assembly machines an attractive option for companies that need to frequently switch between different products or handle low-volume, high-mix production runs. The ability to quickly retool and adjust the machine to meet new requirements ensures that production can continue smoothly without long downtime periods.

4. Cost Efficiency

When compared to larger, traditional assembly machines, mini assembly machines are often more cost-effective. Their smaller size and simpler design mean that they require less material and fewer resources to produce. Furthermore, the lower purchase cost makes them accessible to a wider range of businesses, particularly those that are just starting to implement automation or want to upgrade existing processes without making a massive financial commitment.

Additionally, mini assembly machines can reduce labor costs by automating repetitive tasks that would otherwise require human workers. This not only improves efficiency but also frees up employees to focus on higher-value activities.

5. Improved Worker Safety

Mini assembly machines can also improve worker safety. By automating tasks that are physically demanding or dangerous, these machines reduce the risk of workplace injuries. For example, in industries where workers need to handle sharp objects, heavy machinery, or toxic materials, mini assembly machines can take over these tasks, allowing workers to focus on more strategic aspects of the production process.

Moreover, mini assembly machines are often equipped with built-in safety features such as emergency stop buttons, sensors, and protective covers, ensuring that operators can work safely around the equipment.

Industries Benefiting from Mini Assembly Machines

1. Electronics

The electronics industry is one of the biggest beneficiaries of mini assembly machines. From assembling printed circuit boards (PCBs) to inserting components into small devices like smartphones, tablets, and wearables, these machines are essential for ensuring that products are assembled with high precision and consistency. As electronics continue to get smaller and more complex, the need for compact, efficient assembly machines will only increase.

2. Automotive

In the automotive industry, mini assembly machines are used for a variety of tasks, including assembling small parts like sensors, switches, and connectors. These machines can be integrated into larger production lines or used in specialized, low-volume production settings where high precision is required. As the automotive industry shifts toward electric vehicles and more intricate technologies, mini assembly machines will play a crucial role in keeping pace with these changes.

3. Medical Devices

Mini assembly machines are crucial in the medical device sector, where precision and cleanliness are paramount. These machines are used to assemble everything from small surgical tools to complex diagnostic equipment. Given the stringent regulations in the medical industry, mini assembly machines help ensure that products meet the highest standards of quality and safety.

4. Consumer Goods

From assembling small household appliances to intricate toys and gadgets, mini assembly machines are also used extensively in the consumer goods sector. These machines enable manufacturers to quickly produce high-quality products that meet consumer demands, all while maintaining cost-effectiveness.

Choosing the Right Mini Assembly Machine Supplier

Selecting the right mini assembly machine supplier is critical to ensuring that you get a machine that meets your specific needs. Here are a few key factors to consider when choosing a supplier:

1. Experience and Expertise

A supplier with years of experience in the industry will be better equipped to understand your specific requirements and recommend the right machine for your application. Look for suppliers who have a proven track record of working with businesses in your industry, as they will be more familiar with the challenges and demands you face.

2. Customization Options

Not all assembly tasks are the same, so the ability to customize the machine to your exact needs is important. A good mini assembly machine supplier should offer flexibility in terms of machine design, tooling, and programming. This allows you to tailor the machine to your production process, ensuring optimal efficiency.

3. Support and Service

After-sales support is crucial when investing in machinery. Ensure that the supplier offers comprehensive training, maintenance, and technical support services. This can save you time and money in the long run, as you can rely on their expertise to troubleshoot any issues that arise.

4. Quality and Reliability

The reliability of the machines is another important consideration. Look for a supplier who uses high-quality components and materials in their machines. This will ensure that your mini assembly machine operates smoothly and lasts for years without frequent breakdowns.

5. Price and Value

While price is always a factor, it’s important to consider the overall value the machine will provide. A low-priced machine may have a higher total cost of ownership if it’s prone to breakdowns or requires expensive repairs. It’s often worth investing in a slightly more expensive machine if it offers better durability, precision, and efficiency in the long run.

Conclusion

Mini assembly machines are rapidly becoming a crucial tool in modern manufacturing, offering a host of benefits such as increased efficiency, precision, and cost savings. As manufacturers continue to seek ways to improve productivity and meet customer demands, the importance of these machines will only grow. By choosing the right mini assembly machine supplier, businesses can take full advantage of these innovations and stay ahead in a competitive marketplace. Whether you are in electronics, automotive, medical devices, or consumer goods, mini assembly machines are changing the way products are made – and the right machine could be the key to unlocking your production potential.